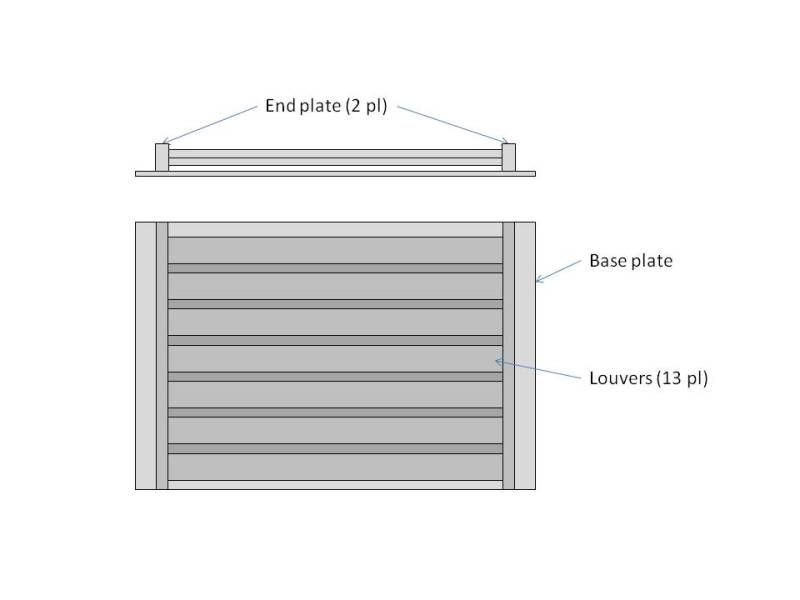

The hardest part was removing the stock plastic louvers. I guess the previous owner went in for the recall and it was silicone glued the hell out off it. The rest was max 20 min for everything.

The hood louver was won from an ebay auction sale going on. It came with instructions and the box said Zmag on it.

Here are the results:

The chrome is a little to bling for me but I'll just leave it for now as it matches the grill little bit.

The only concern I have is the driver side vent sits pretty close to the Alternator. Not sure how safe that will be when it rains.

Also the new piece is heavy and now the hood will not stay opened. I will have to look into heavy duty struts for the hood.

The hood louver was won from an ebay auction sale going on. It came with instructions and the box said Zmag on it.

Here are the results:

The chrome is a little to bling for me but I'll just leave it for now as it matches the grill little bit.

The only concern I have is the driver side vent sits pretty close to the Alternator. Not sure how safe that will be when it rains.

Also the new piece is heavy and now the hood will not stay opened. I will have to look into heavy duty struts for the hood.