SuperBuickGuy

Well-Known Member

- Messages

- 3,403

- Location

- Woodinville, WA

I went with Spartan lockers front and rear... no electrics, no air hoses, no clever springs... no sliding down roads backwards... just amazing understeer under power.

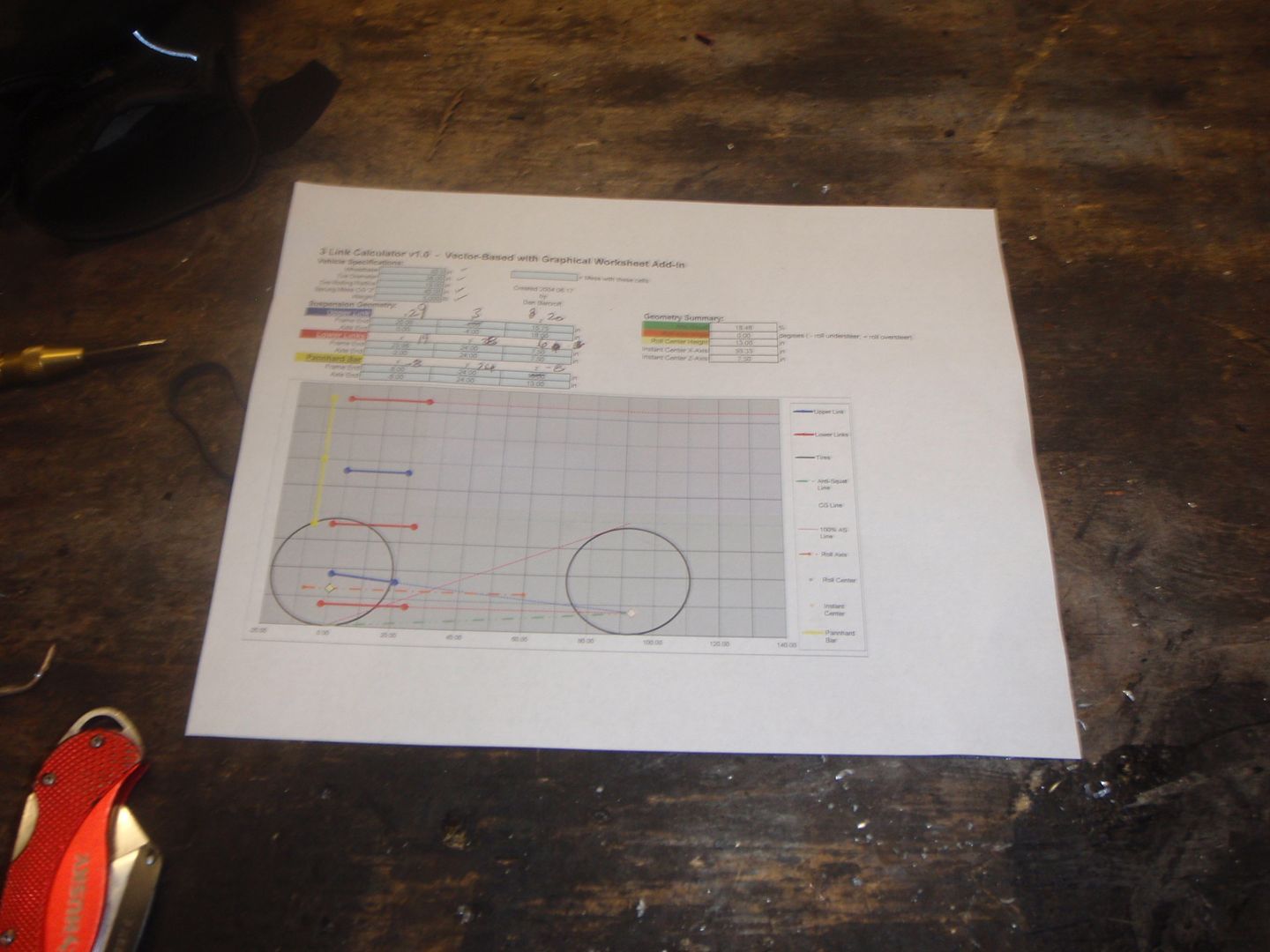

| 4 Bar Linkage Calculator v3.0 | � | ||||

| Vehicle CG | 40.00 | ||||

| Sprung Mass CG | 49.00 | in | |||

| Anti-Squat CG | 43.42 | in | |||

| Suspension Geometry: | � | ||||

| Upper Links | x | y | z | ||

| Frame End | 23.000 | 15.000 | 26.000 | in | |

| Axle End | 0.000 | 4.500 | 26.000 | in | |

| Vector | 23.000 | 10.500 | 0.000 | in | |

| Length | 25.283 | in | |||

| Unit Vector | 0.9097 | 0.4153 | 0.0000 | 1.0000 | |

| Intercept | -9.8571 | 4.5000 | 26.0000 | in | |

| Roll Point | -9.8571 | 0.0000 | 26.0000 | in | |

| Force | 6183.439 | lb (Tension) | |||

| Force Vector | 5625.000 | 2567.935 | 0.000 | lb | |

| Vertical Slope | 0.4565 | in/in | |||

| Horizontal Slope | 0.0000 | in/in | |||

| Lower Links | x | y | z | ||

| Frame End | 33.000 | 3.750 | 21.000 | in | |

| Axle End | 3.000 | 15.500 | 18.000 | in | |

| Vector | 30.000 | -11.750 | 3.000 | in | |

| Length | 32.358 | in | |||

| Unit Vector | 0.9271 | -0.3631 | 0.0927 | 1.0000 | |

| Intercept | 42.5745 | 16.6750 | 17.7000 | in | |

| Roll Point | 42.5745 | 0.0000 | 21.9574 | in | |

| Force | -8446.958 | lb (Compression) | � | ||

| Force Vector | -7831.325 | 3067.269 | -783.133 | lb | |

| Vertical Slope | -0.3917 | in/in | |||

| Horizontal Slope | 0.100 | in/in | |||

| Geometry Summary: | � | ||||

| Anti-Squat | 68.179 | % | |||

| Roll Axis Slope | -0.0771 | in/in (Roll Understeer) | � | ||

| Roll Center Height | 25.240 | in | |||

| Roll Axis Angle | -4.409 | degrees (Roll Understeer) | � | ||

| Instant Center X-Axis | 83.000 | in | |||

| Instant Center Z-Axis | 26.000 | in | � |