SuperBuickGuy

Well-Known Member

- Messages

- 3,403

- Location

- Woodinville, WA

so I can start on the little things.

full droop

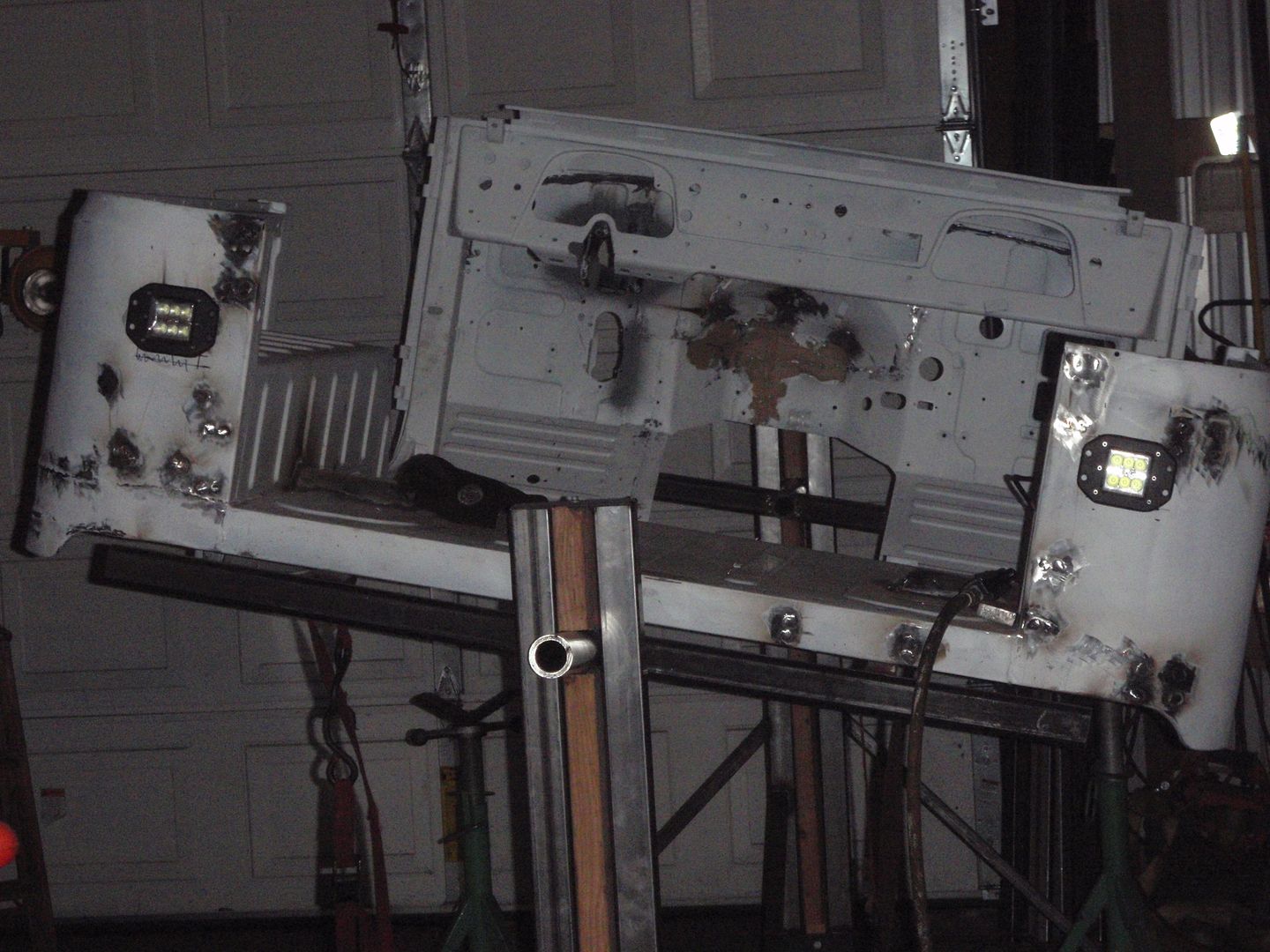

the back looks great

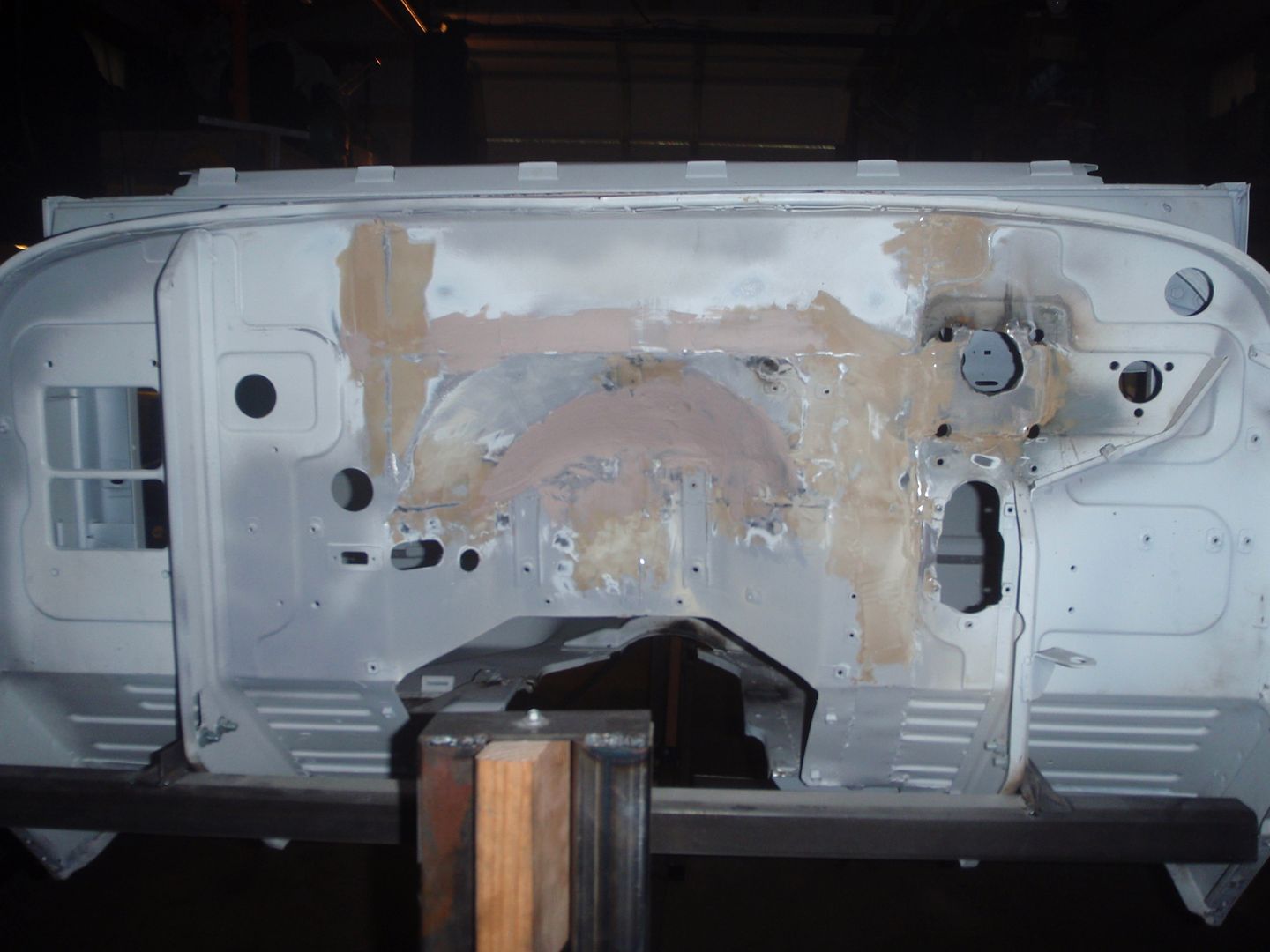

front, I'm not happy with this. because of the angle of the steering cross shaft, the panhard bar needs to parallel it

the problem is the front axle will move left as the suspension drops. It will feel weird, but it could be quite an adventure if I was jumping sand dunes with it like this.... the issue was/is that it doesn't seem there are many drop steering arms for the Scout 2 box. I've found one that might work, but I think, before I spend the dollars, I will bend my original one to 4" drop and see what I see. I'll have to extend the frame mount down to get the panhard parallel with it... if it works, I may either simply bend the part I have now (which requires sand and careful cooling) or buy the "right one" though the "right" one may not be long enough.... ah well, if it were easy, it'd be on pirate.

What do you think, Speedy?

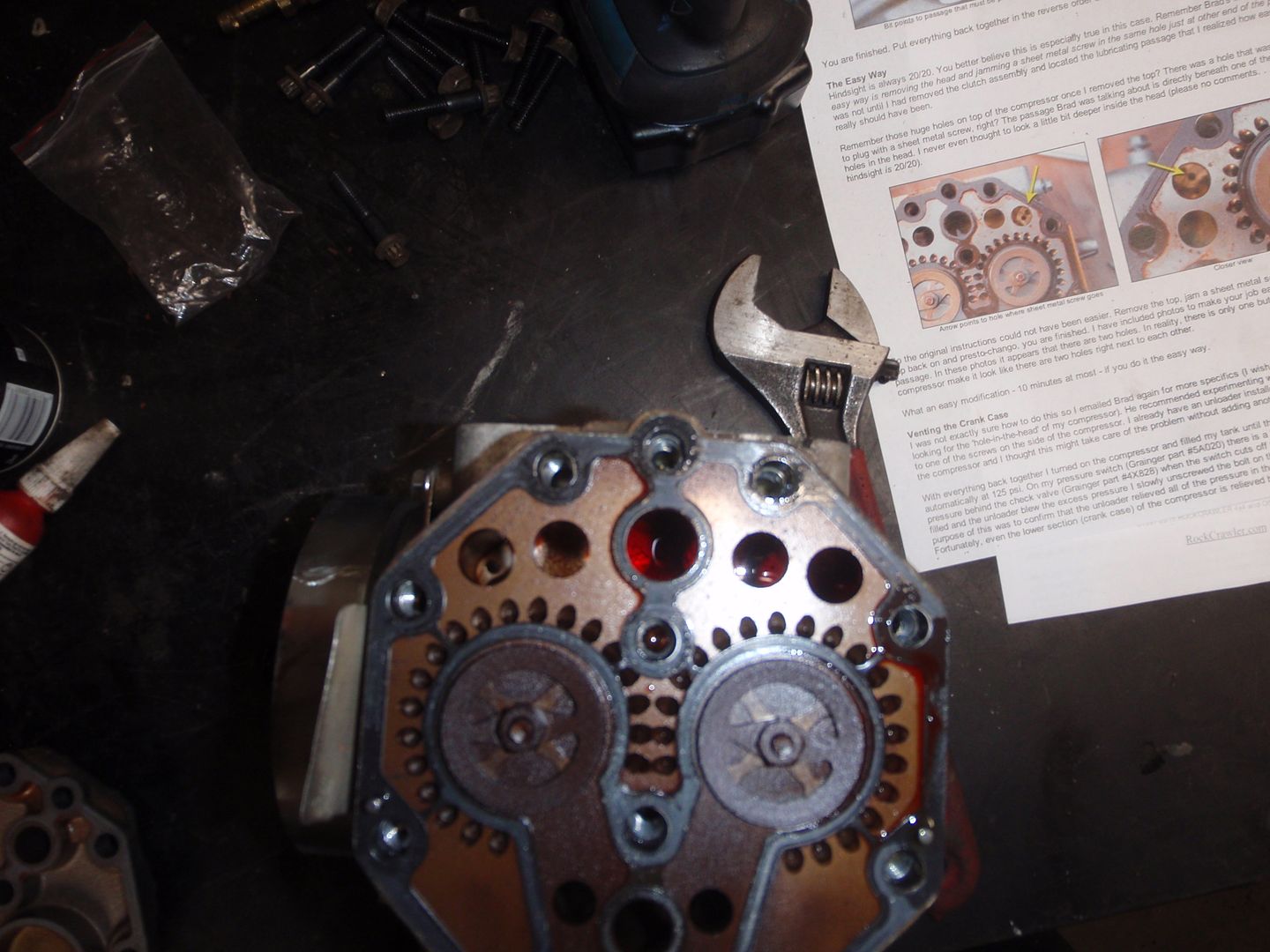

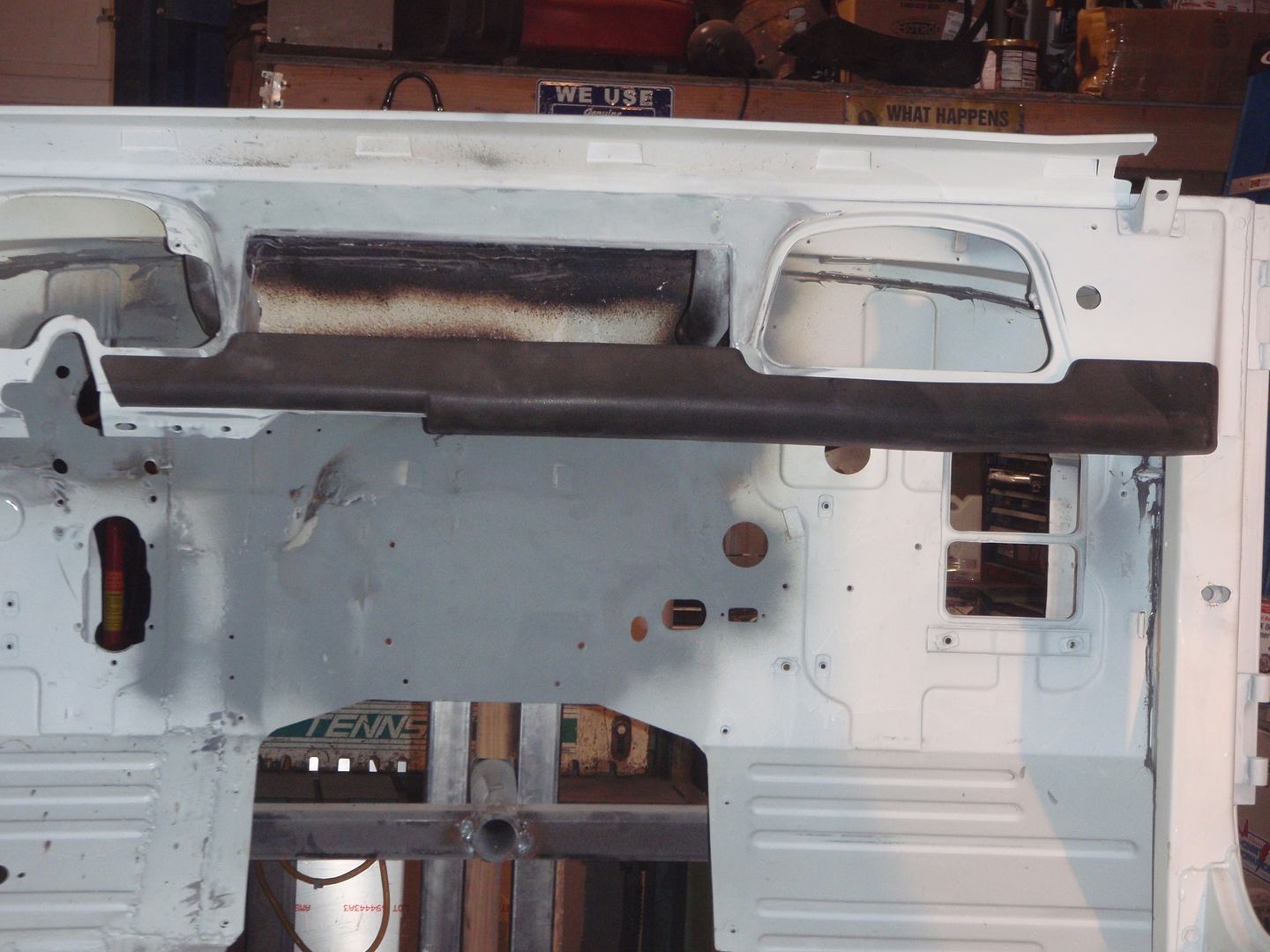

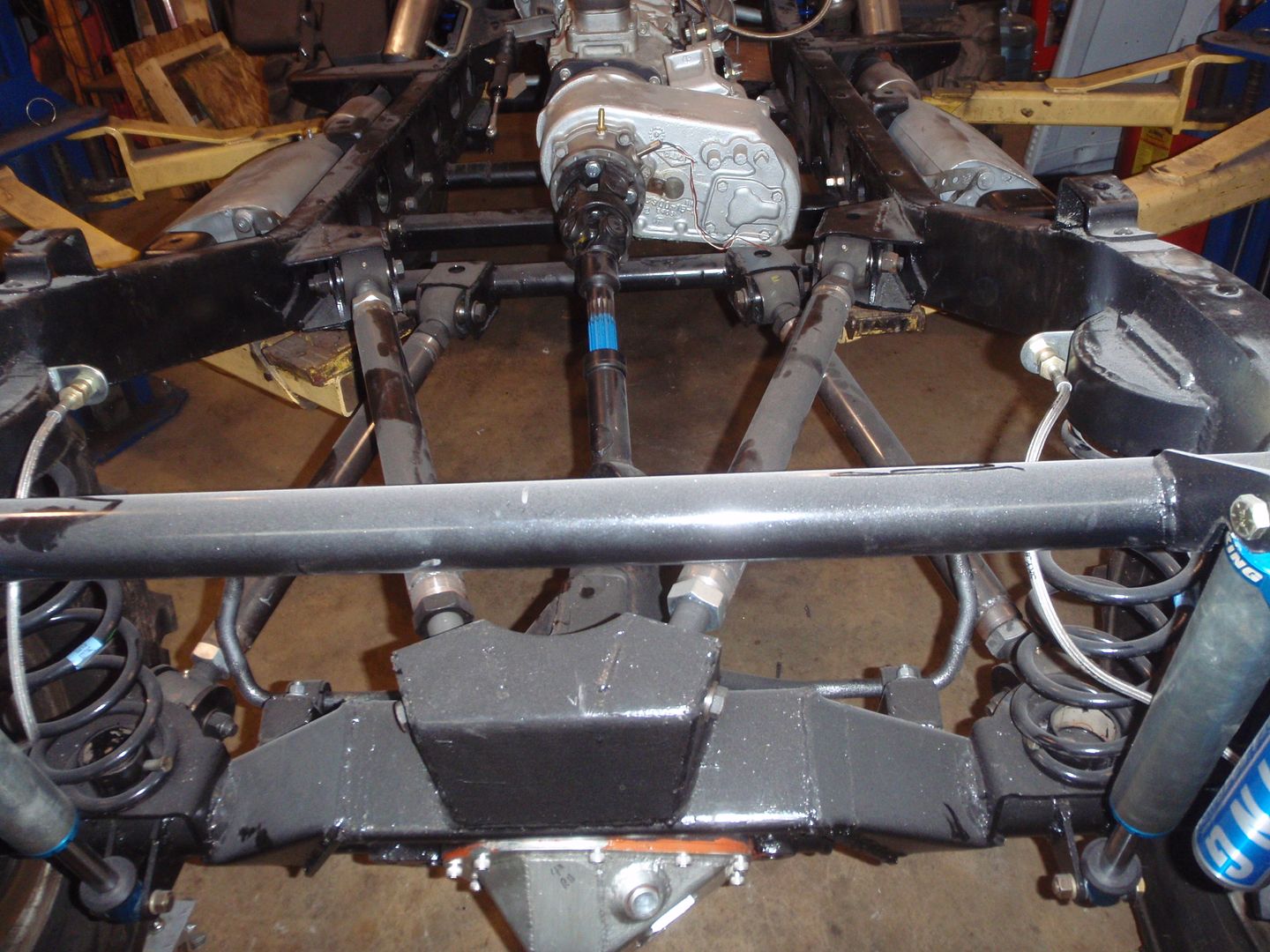

in other news, the notch seems fine except I need to do a bit of clearancing at the transmission

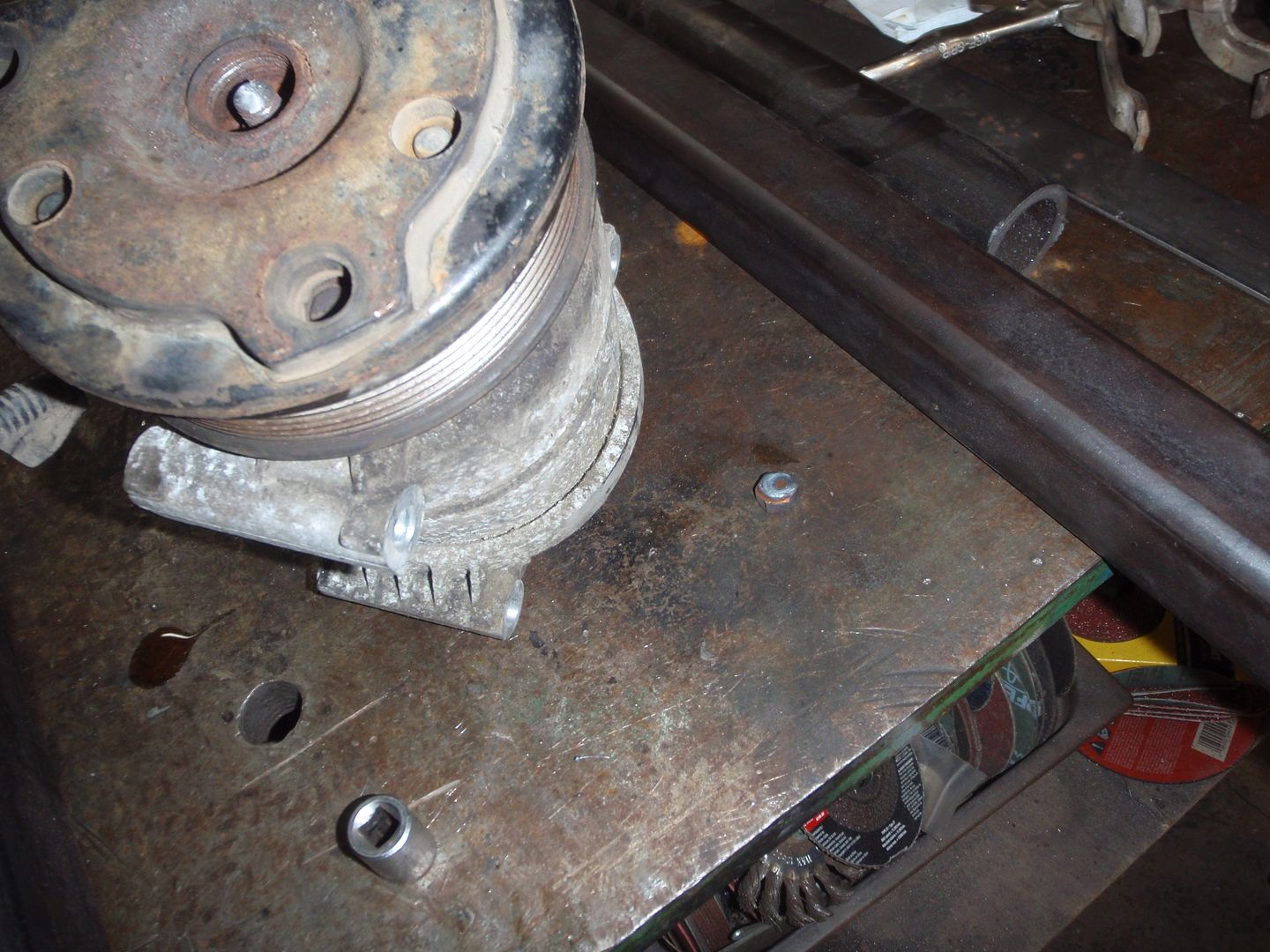

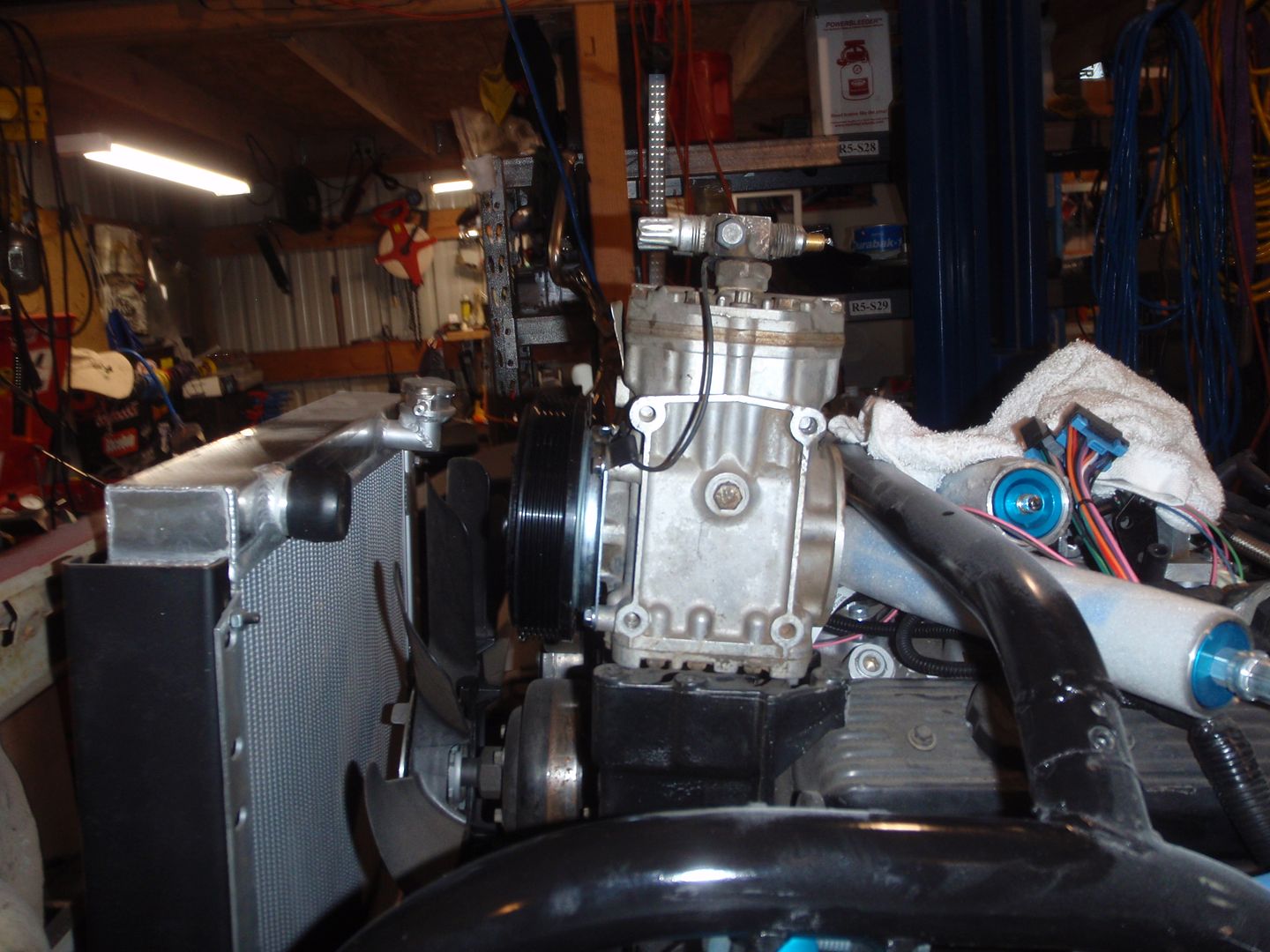

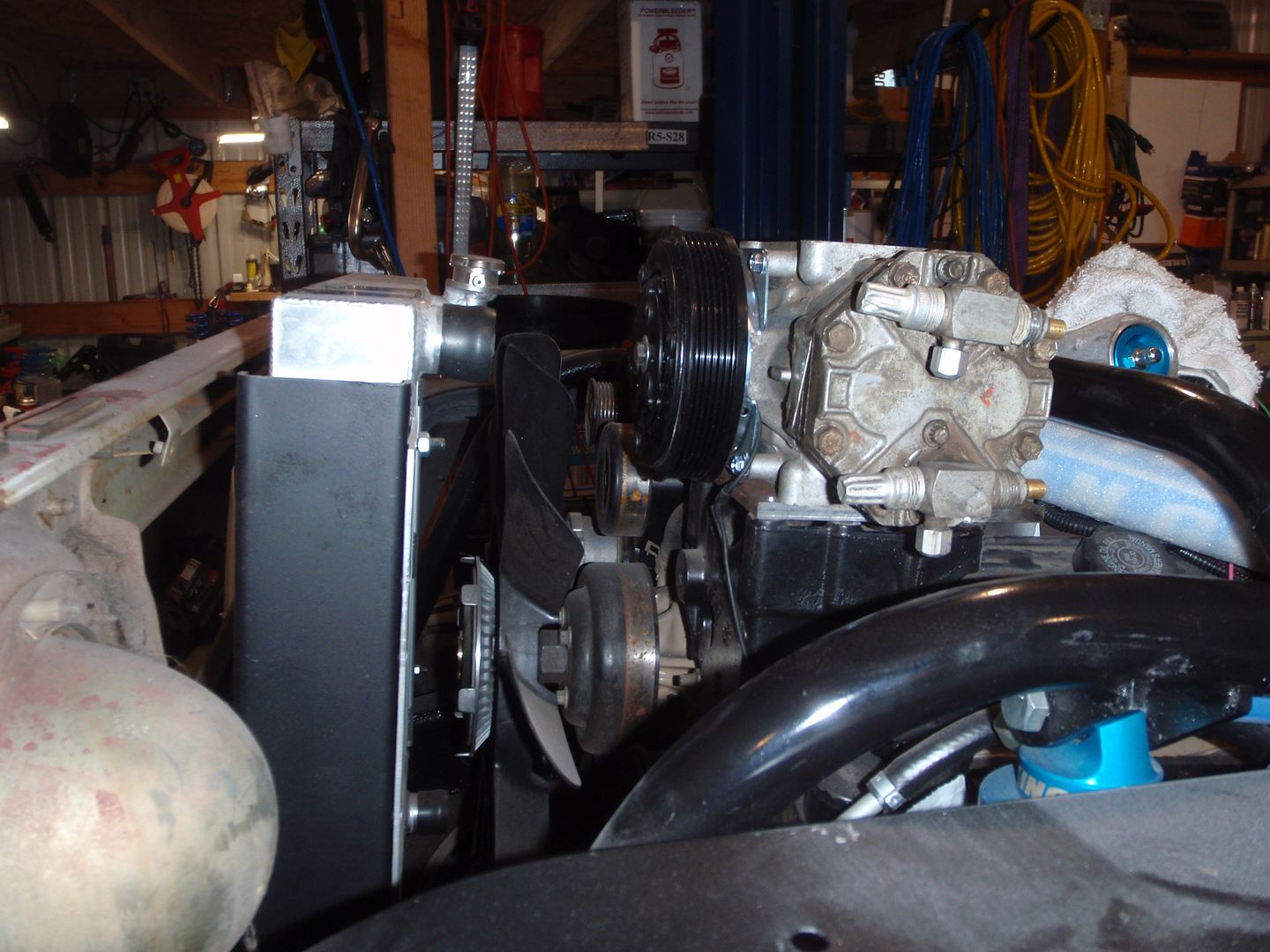

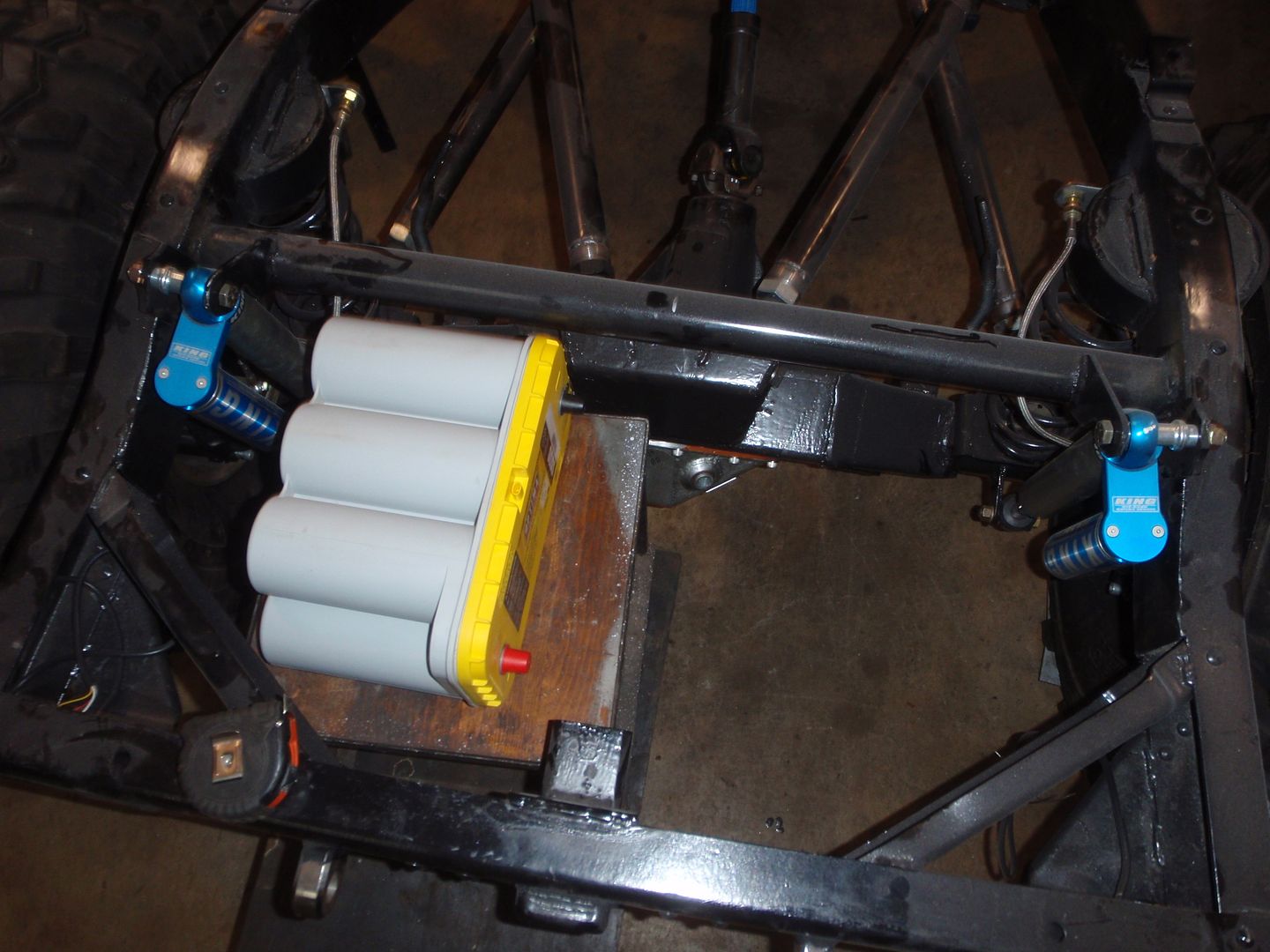

and the only thing I really got forward movement on was this

and that was more of a sideways movement

I spent the day learning how to better save people who do stupid things.... not sure why I did that, but it's what got in the way of doing more on this...

full droop

the back looks great

front, I'm not happy with this. because of the angle of the steering cross shaft, the panhard bar needs to parallel it

the problem is the front axle will move left as the suspension drops. It will feel weird, but it could be quite an adventure if I was jumping sand dunes with it like this.... the issue was/is that it doesn't seem there are many drop steering arms for the Scout 2 box. I've found one that might work, but I think, before I spend the dollars, I will bend my original one to 4" drop and see what I see. I'll have to extend the frame mount down to get the panhard parallel with it... if it works, I may either simply bend the part I have now (which requires sand and careful cooling) or buy the "right one" though the "right" one may not be long enough.... ah well, if it were easy, it'd be on pirate.

What do you think, Speedy?

in other news, the notch seems fine except I need to do a bit of clearancing at the transmission

and the only thing I really got forward movement on was this

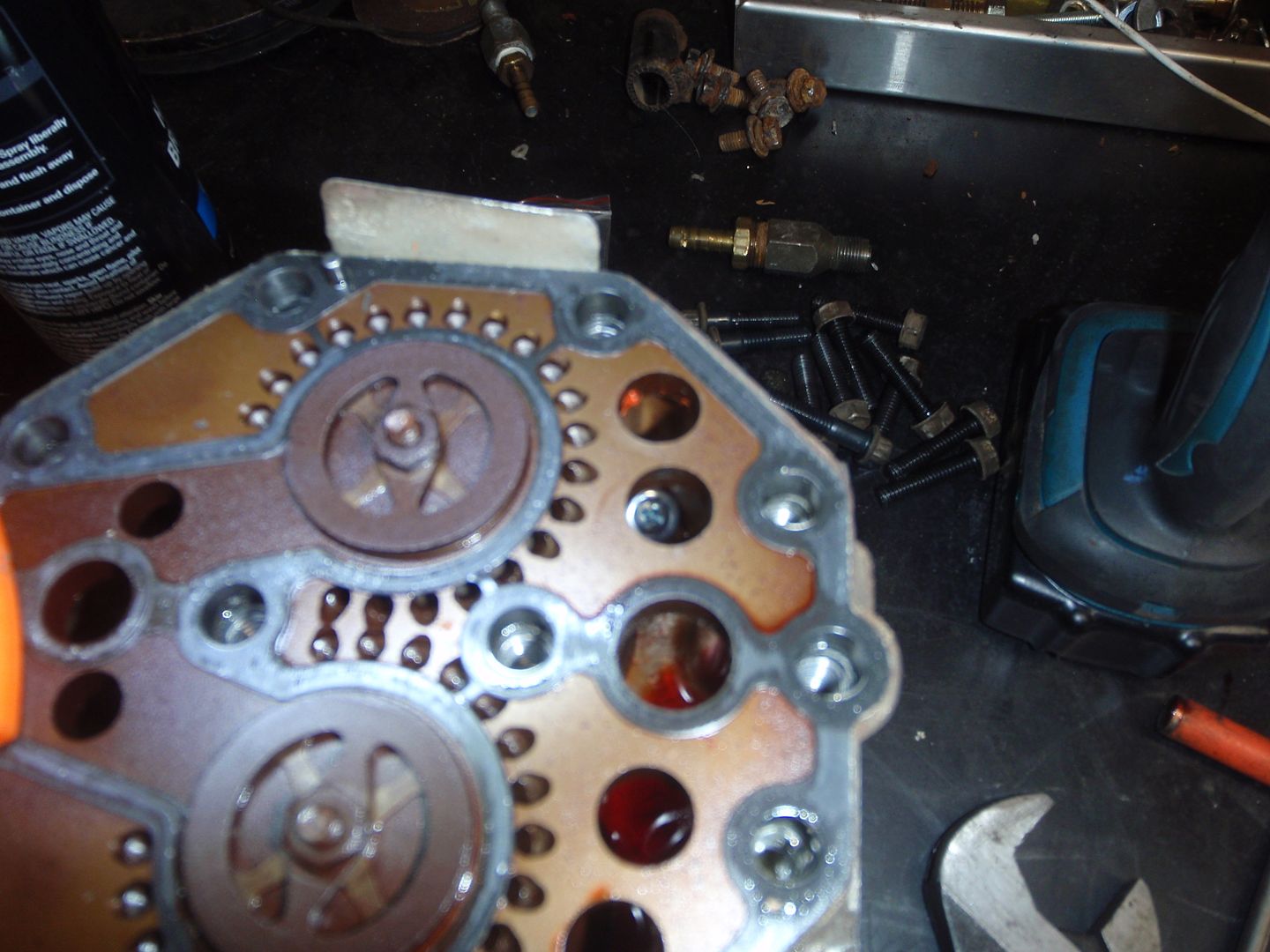

and that was more of a sideways movement

I spent the day learning how to better save people who do stupid things.... not sure why I did that, but it's what got in the way of doing more on this...