I neglected to mention earlier that I have a new family member!

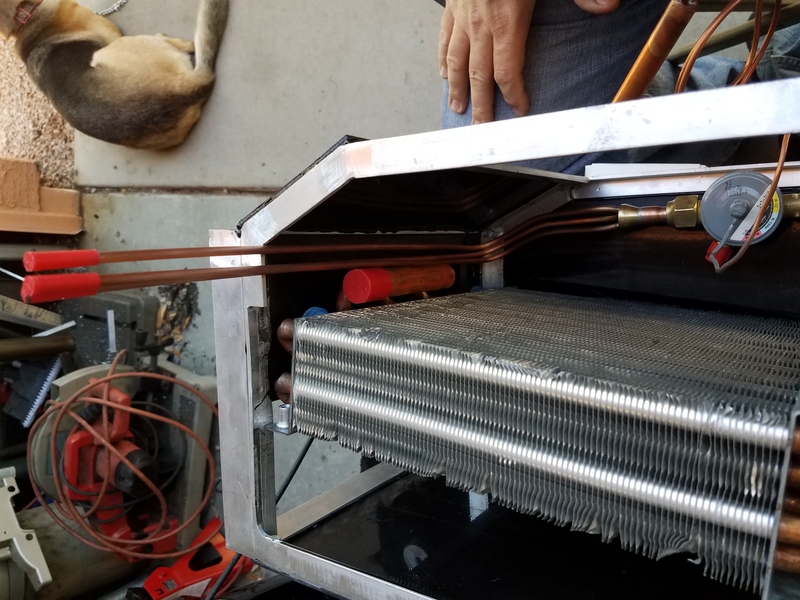

Her name is Freya, and she does an excellent job of holding down the floor while I work:

She is a 3-½ year old German Shepherd who was at a rescue shelter. She is great with kids and cats, and she has a good sense of people and she has definitely become protective of her new family. She is also very intelligent. I am looking forward to taking her camping with us. I think she will really like hanging out in the forest. Unfortunately, the weather is heating up fast, and when she rides in my truck her attitude is "Dude! Get me some AC goin' in this thing!"

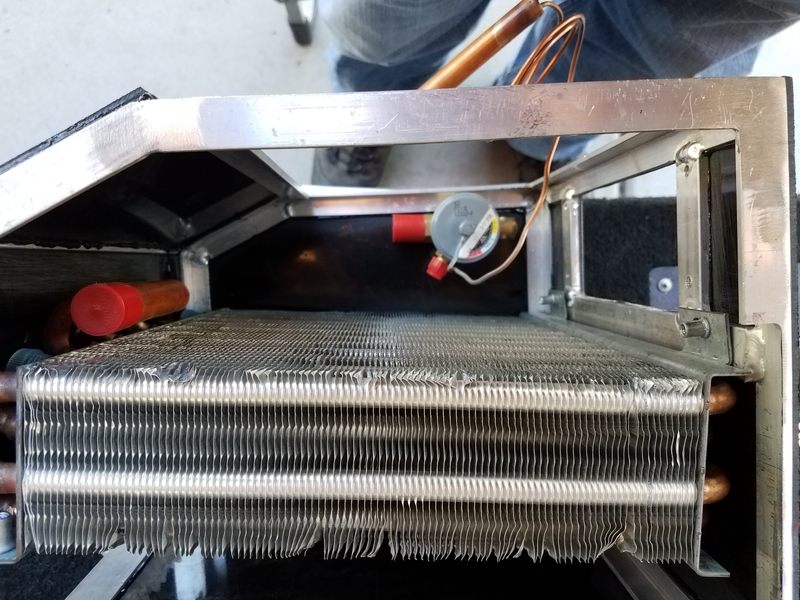

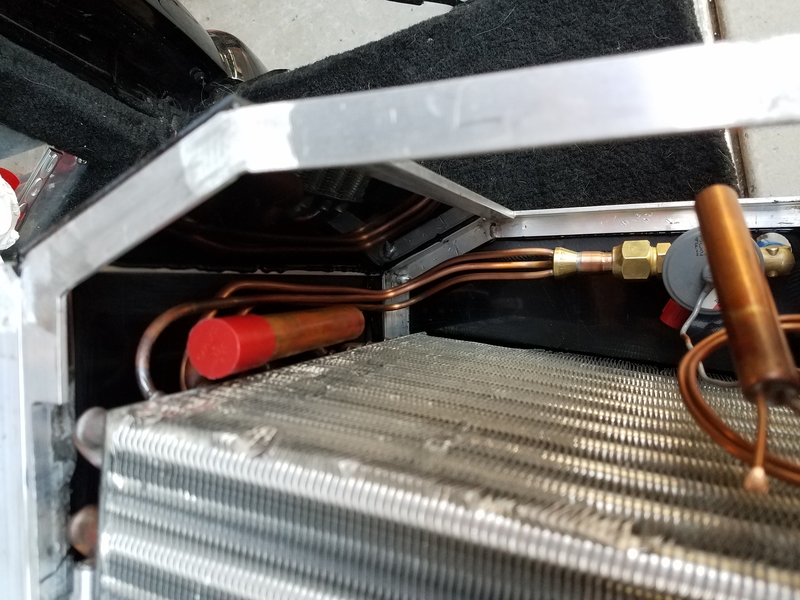

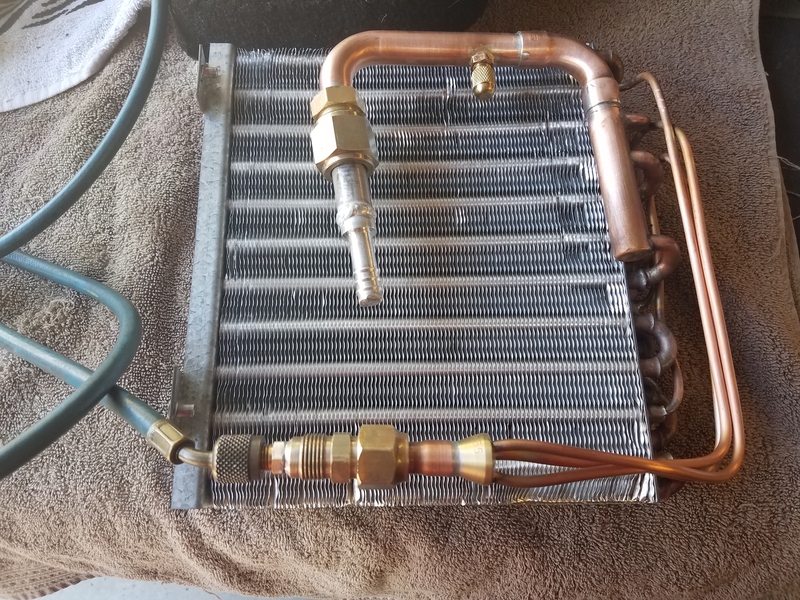

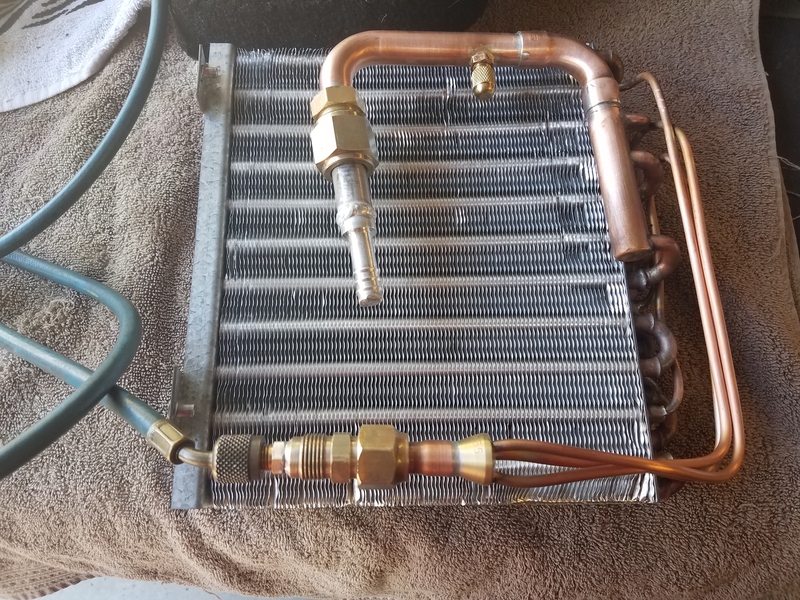

With that said, I got the evaporator finished. I was originally going to run the suction line out the back as one piece, but I quickly realized it would be impossible go get the evaporator in or out of the housing. I ended up running a horizontal section of suction line long enough to accommodate the TXV bulb then turning it down and putting the -12 brass female o-ring fitting on the end. With the exception of the Schrader fitting, which is brazed on with 56% silver braze, all of the suction piping is soldered together with Harris Stay Brite silver solder. Stay Brite is designed for HVACR service and because it takes much less heat to melt there was no danger of accidentally melting the braze joints between the header and the three tubes exiting the evaporator. After I got it soldered and brazed, I used my pressure test fittings to plug up the inlet and outlet and pressurized the whole unit:

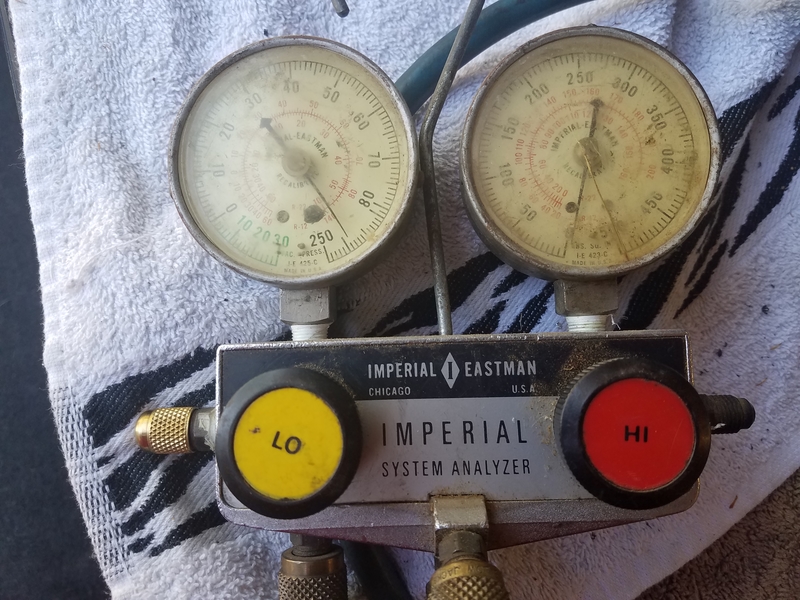

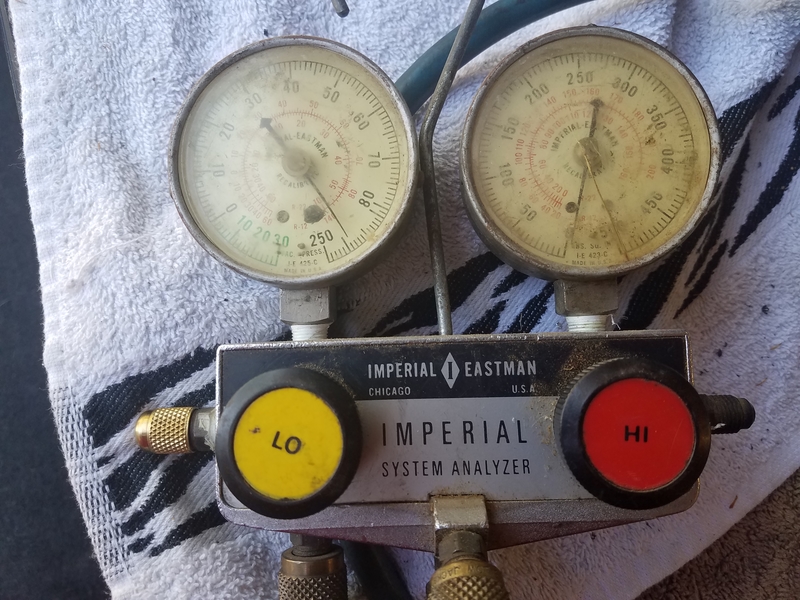

I found my old Imperial gauge set and chose to use it to pressure test the system. Despite being over 35 years old, the manifold doesn't leak. My JB manifold leaks, and my Yellow Jacket manifold has a broken low side gauge. They are both on my to-do list to fix. Whether they will get fixed depends on if I decide to invest in a Testo 550 or a Sporlan SMART tools setup to attach to the Imperial manifold. Anyway, I digress. Here it is holding ~190psi pressure:

The problem with this gauge set is that it was designed for a better, vanished time. It has saturated temperatures for R-12 and R-22, and the gauges start to retard after 80psi, at which point they're not very accurate or responsive. I tried running my JB manifold with brand new R-410a gauges that read to 250psi on the low side with no retarding, but then I discovered that the low side valve seal leaks. I ended up putting the Imperial set back on and pressurizing the evaporator to 75psi. It has now been a couple days and the gauge is holding pressure, so I think I can pronounce the evaporator coil leak-free.

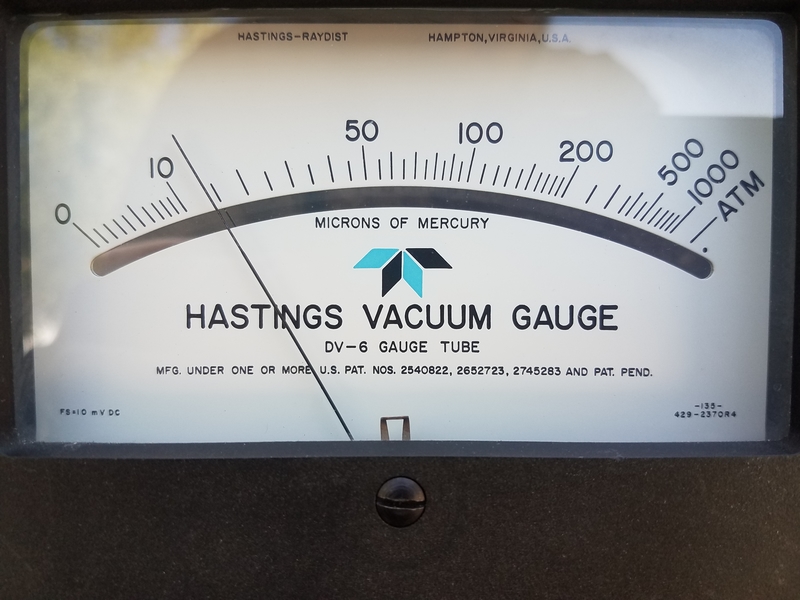

I also got myself a new micron vacuum gauge. Back when I got into refrigeration and AC nobody had micron gauges because they were expensive. Turns out they are still expensive, but cheaper than they used to be. After having seen how different two new digital gauges from the same manufacturer can read on the same line, I chose to go with a laboratory-type instrument. If I get a cheap, compact digital gauge I can use this instrument to sanity check it.

I decided to use my new gauge to see how low of a vacuum my over-20-years-old vacuum pump can pull. Here's the gauge tube attached to the pump:

I tried initially with the oil in the pump, and was only able to pull 180 microns. I dumped the oil and filled the pump with some old (but unused in a sealed bottle) oil I had lying around. The pump holds a quart, and I had 3/4 quart of VERY high quality and very expensive Inland 45 synthetic pump oil in the cabinet. I poured it in the pump, and topped it off with ¼ quart of cheap Robinair vacuum pump oil that had been kicking around in a cabinet for 10 years. The Robinair oil is nowhere near the quality of Inland 45, but the pump still managed to pull a very respectable vacuum:

14 microns! It actually pulled down to 11 a few minutes after I snapped that pic, at which point I shut it down. For a relatively inexpensive refrigeration service pump that is an excellent vacuum. Assuming the AC system doesn't leak I should have no problems pulling down to 250 microns.

That's all for now. Hopefully the next update will be to show the evap housing mounted under the dash.