MaxPF

AGNTSA

- Messages

- 1,394

- Location

- The dark side of the globe

This is my new new build thread, since the old one ended up turning into a mess. This time we will start from the beginning...

Way back in 2006 I acquired a white 1991 K5 Blazer with a TBI 350 and a blown-up 700R4 automatic.. Actually, by this time GM was calling it a V1500, which reflected the fact that it was an old body style vs the new body pickups that came out in 1988. The 4WD new body trucks got the "K" designation, so the old body 4WDs got the "V" designation. The "1500", then as now, denoted a 1/2 ton chassis. It was a Silverado package truck, which meant power-everything and alloy wheels. Here's what she looked like back in the day:

As you can see, it was clean and straight. With a rebuilt trans it ran good as well, and it became my hunting and camping rig:

5-star hunting accommodations:

Then, one day it decided to spring a waterfall out of the drivers side head gasket :roll: With a truck I find it's easier to pull the engine to replace head gaskets, so that's what I did:

Pics with the heads removed:

Doesn't look to bad, eh? Well, take a closer peek at the coolant passages, Apparently, the PO didn't believe in cooling system maintenance. When I removed a freeze plug, this is what I saw:

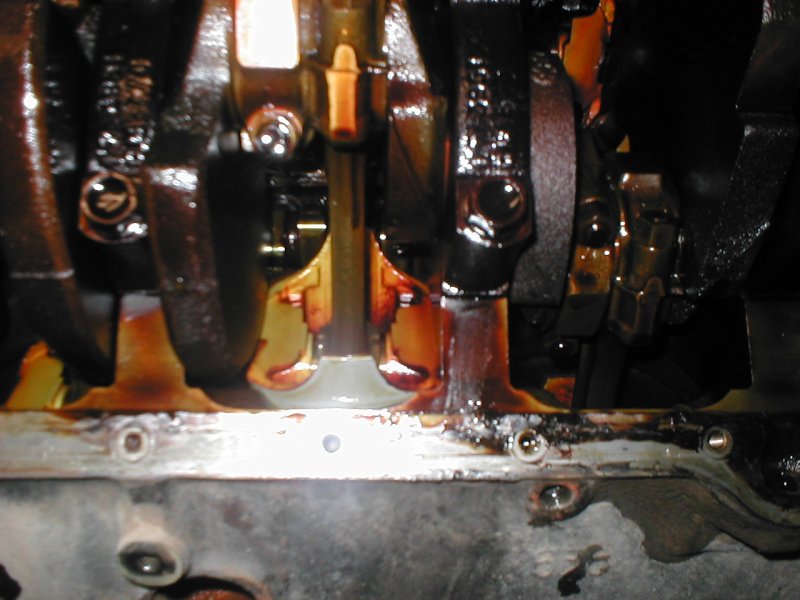

Yuck! It didn't help that this happened right after new years in January of '07 and it was miserably cold and windy :roll: Since the oil pan leaked a bit I decided to pull it off and take a peek in there as well. It got worse:

It seems routine oil changes were also neglected. All that reddish-brown stuff is some kind of varnish-like residue. It was thick and hard (phrasing! :giggle and I have never seen anything like it. That said, the engine had good oil pressure, ran good, didn't burn oil, and passed emissions, so I put it back together. I flushed the block, installed new freeze plugs, and put the pan back on with a new gasket:

and I have never seen anything like it. That said, the engine had good oil pressure, ran good, didn't burn oil, and passed emissions, so I put it back together. I flushed the block, installed new freeze plugs, and put the pan back on with a new gasket:

Likewise, I cleaned and re-assembled the heads and put them back on with new head gaskets:

I put the motor back in the truck and it ran great. I proceeded to wheel it, and at some point incurred some body damage :shame:

Now that I am faced with fixing the accumulated body damage I wish I had never taken the truck out on those trails without a lift. Live and learn, and boy did I learn!

To be continued...

Way back in 2006 I acquired a white 1991 K5 Blazer with a TBI 350 and a blown-up 700R4 automatic.. Actually, by this time GM was calling it a V1500, which reflected the fact that it was an old body style vs the new body pickups that came out in 1988. The 4WD new body trucks got the "K" designation, so the old body 4WDs got the "V" designation. The "1500", then as now, denoted a 1/2 ton chassis. It was a Silverado package truck, which meant power-everything and alloy wheels. Here's what she looked like back in the day:

As you can see, it was clean and straight. With a rebuilt trans it ran good as well, and it became my hunting and camping rig:

5-star hunting accommodations:

Then, one day it decided to spring a waterfall out of the drivers side head gasket :roll: With a truck I find it's easier to pull the engine to replace head gaskets, so that's what I did:

Pics with the heads removed:

Doesn't look to bad, eh? Well, take a closer peek at the coolant passages, Apparently, the PO didn't believe in cooling system maintenance. When I removed a freeze plug, this is what I saw:

Yuck! It didn't help that this happened right after new years in January of '07 and it was miserably cold and windy :roll: Since the oil pan leaked a bit I decided to pull it off and take a peek in there as well. It got worse:

It seems routine oil changes were also neglected. All that reddish-brown stuff is some kind of varnish-like residue. It was thick and hard (phrasing! :giggle

Likewise, I cleaned and re-assembled the heads and put them back on with new head gaskets:

I put the motor back in the truck and it ran great. I proceeded to wheel it, and at some point incurred some body damage :shame:

Now that I am faced with fixing the accumulated body damage I wish I had never taken the truck out on those trails without a lift. Live and learn, and boy did I learn!

To be continued...

Last edited: