woohoo parts to install

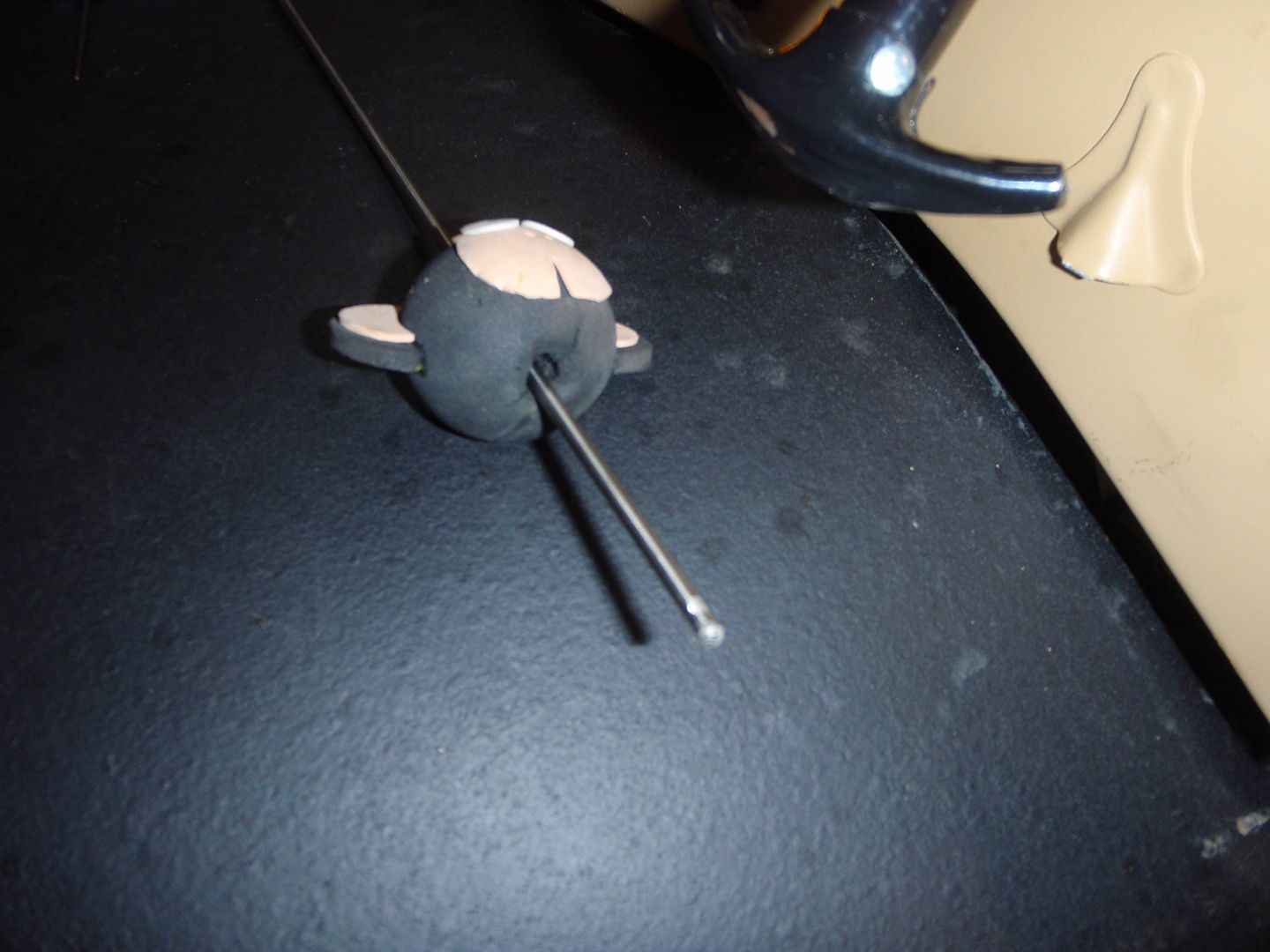

I don't like hooks because they can pop off and kill you.

but I hated the idea of destroying a hook to get it off (why, smittybilt, why?)

as you can see, I got over it

factor 55 builds an end that allows you to use shackles - thus you have a closed-loop-winching situation and it's much, much safer. Also, it allows you to run a license plate (stay tuned for how)

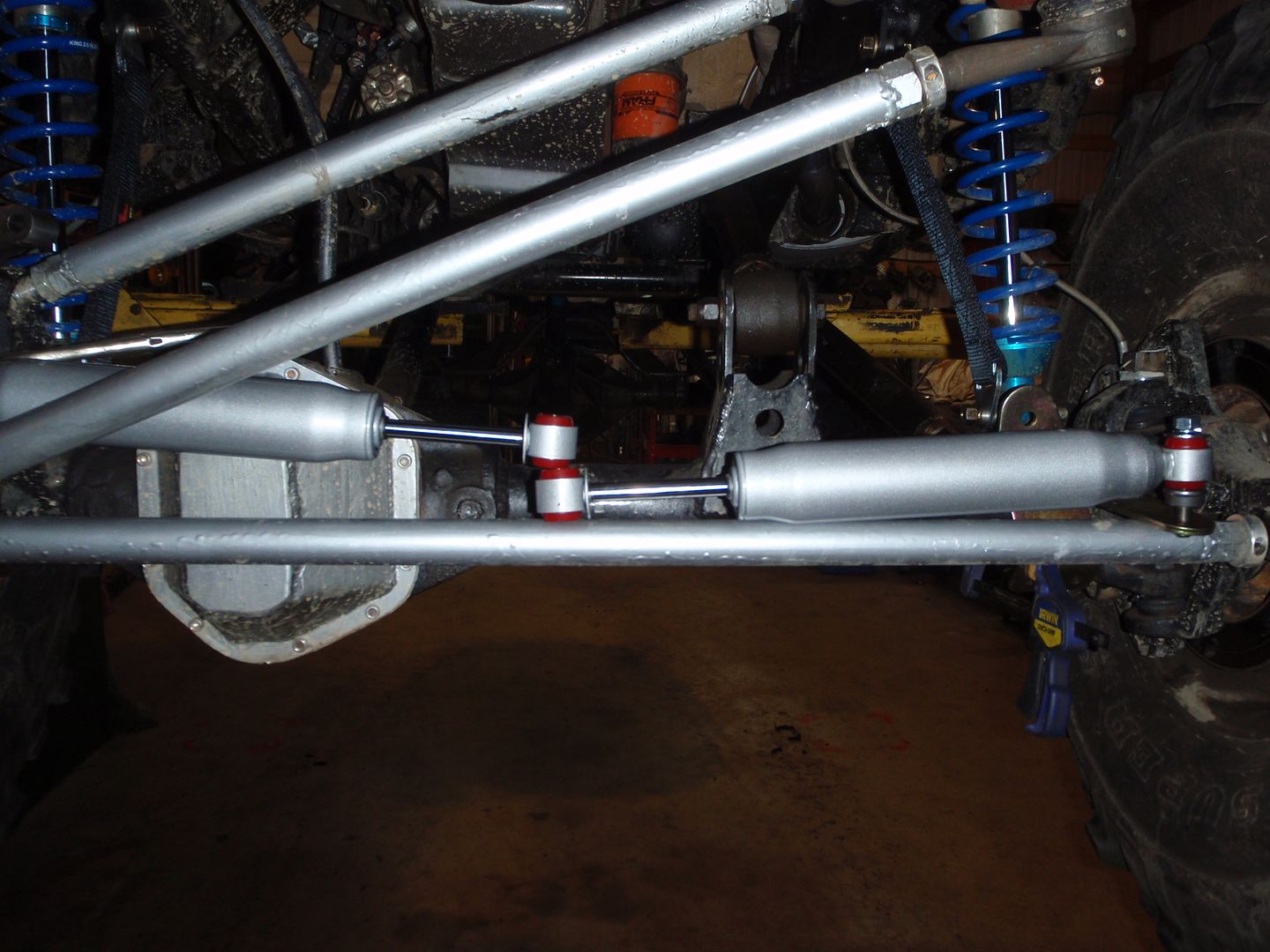

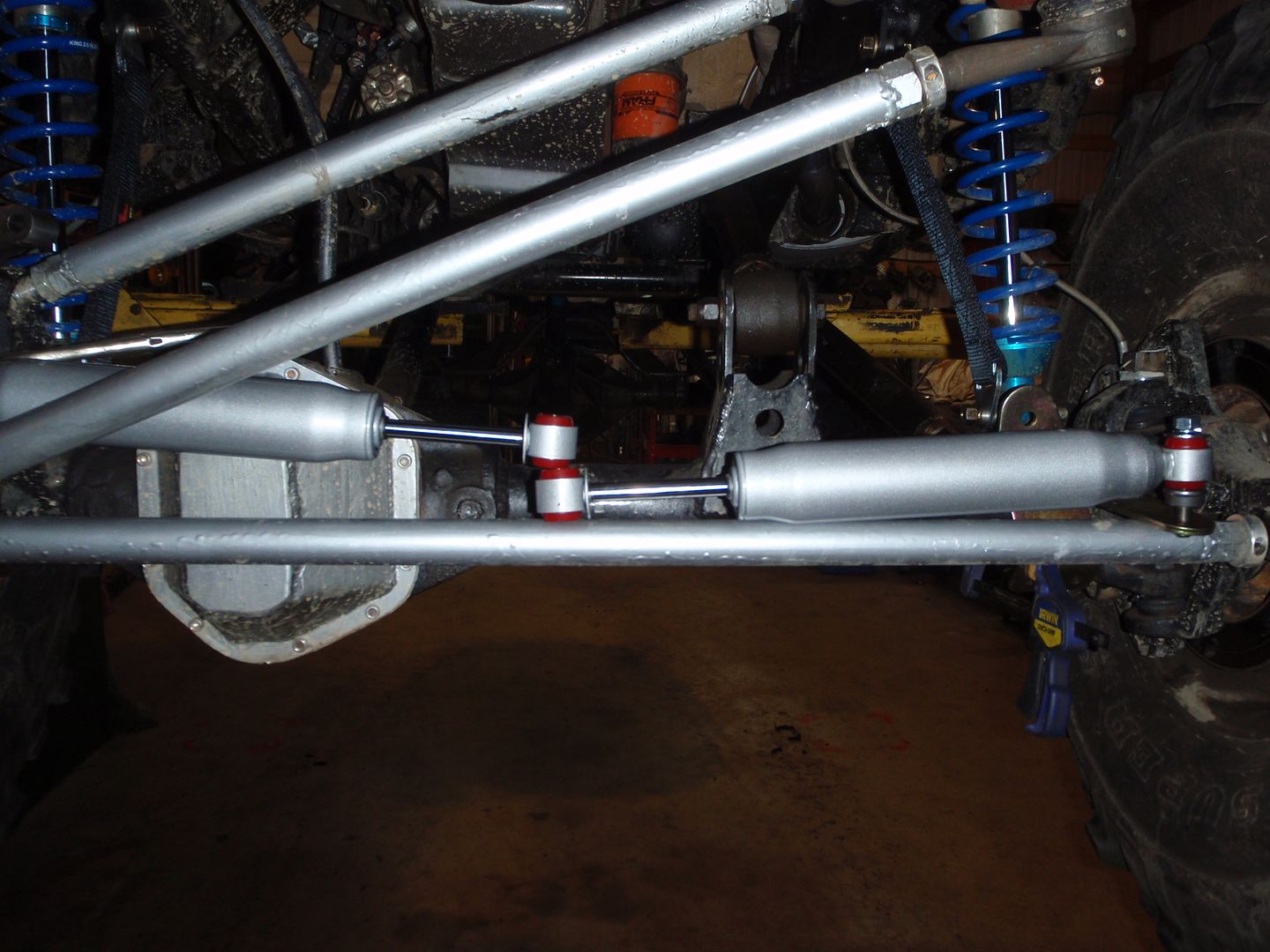

next a stabilizer. I knew I was going to put a stabilizer on it, but I didn't want to band-aid a problem so I drove for awhile without... that said, it does a neat death wobble when you hit a pothole or railroad tracks with one-tire-first.... so I'm fixing that

so I went through these ideas first

before I raided my parts box to create my own - funny, buying 2 stabilizers in a kit is cheaper then buying two stabilizers.

the parts

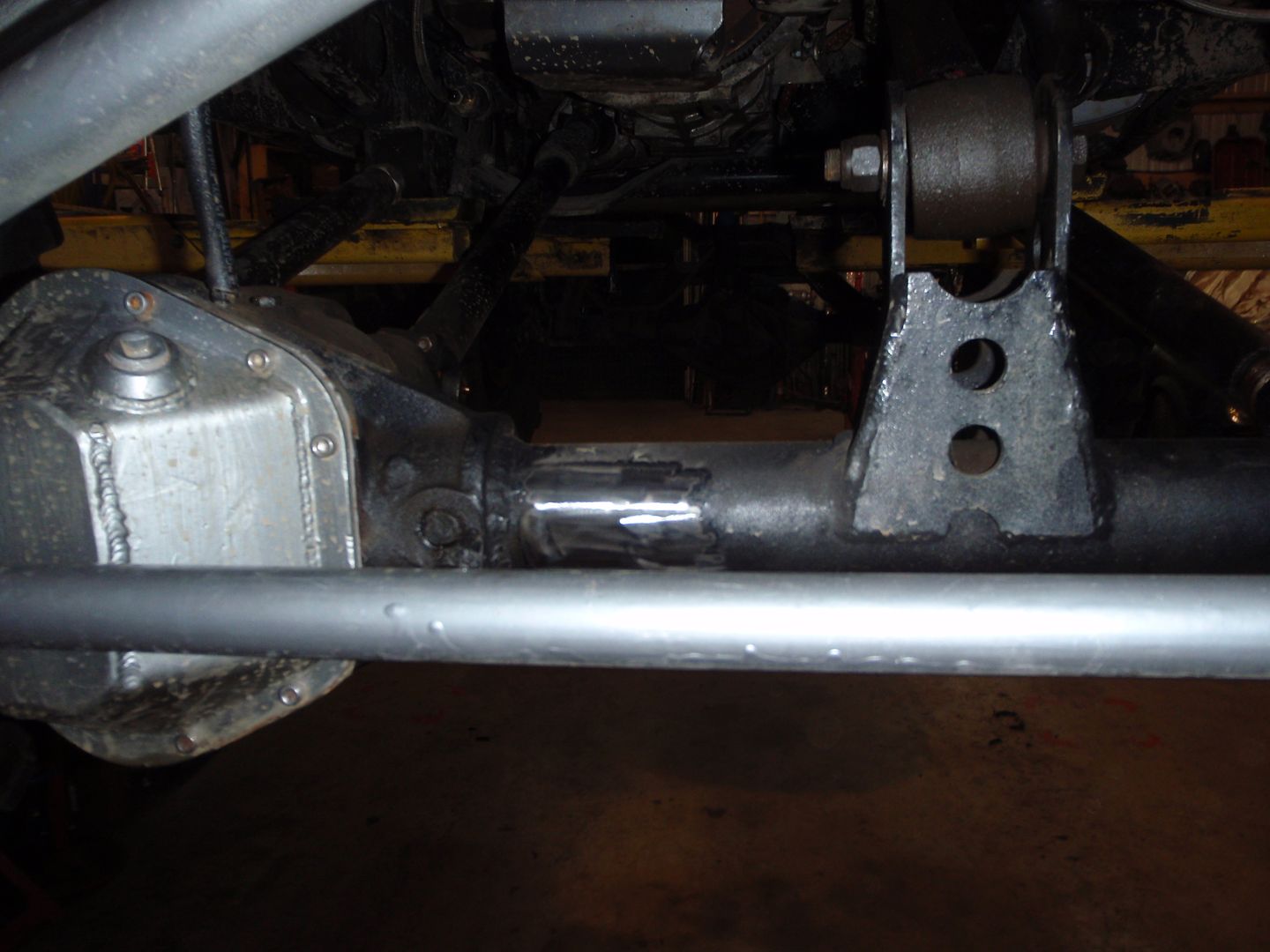

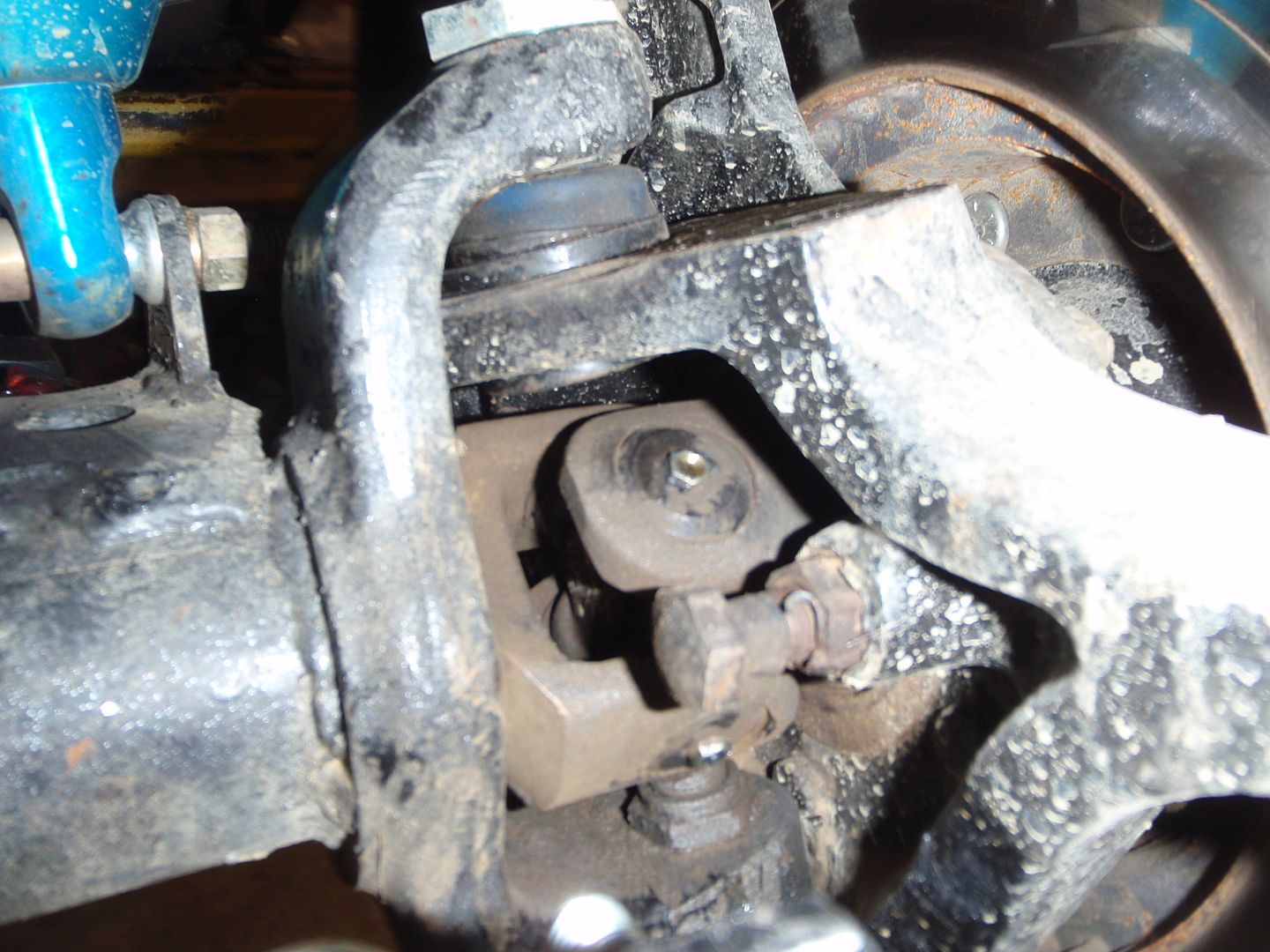

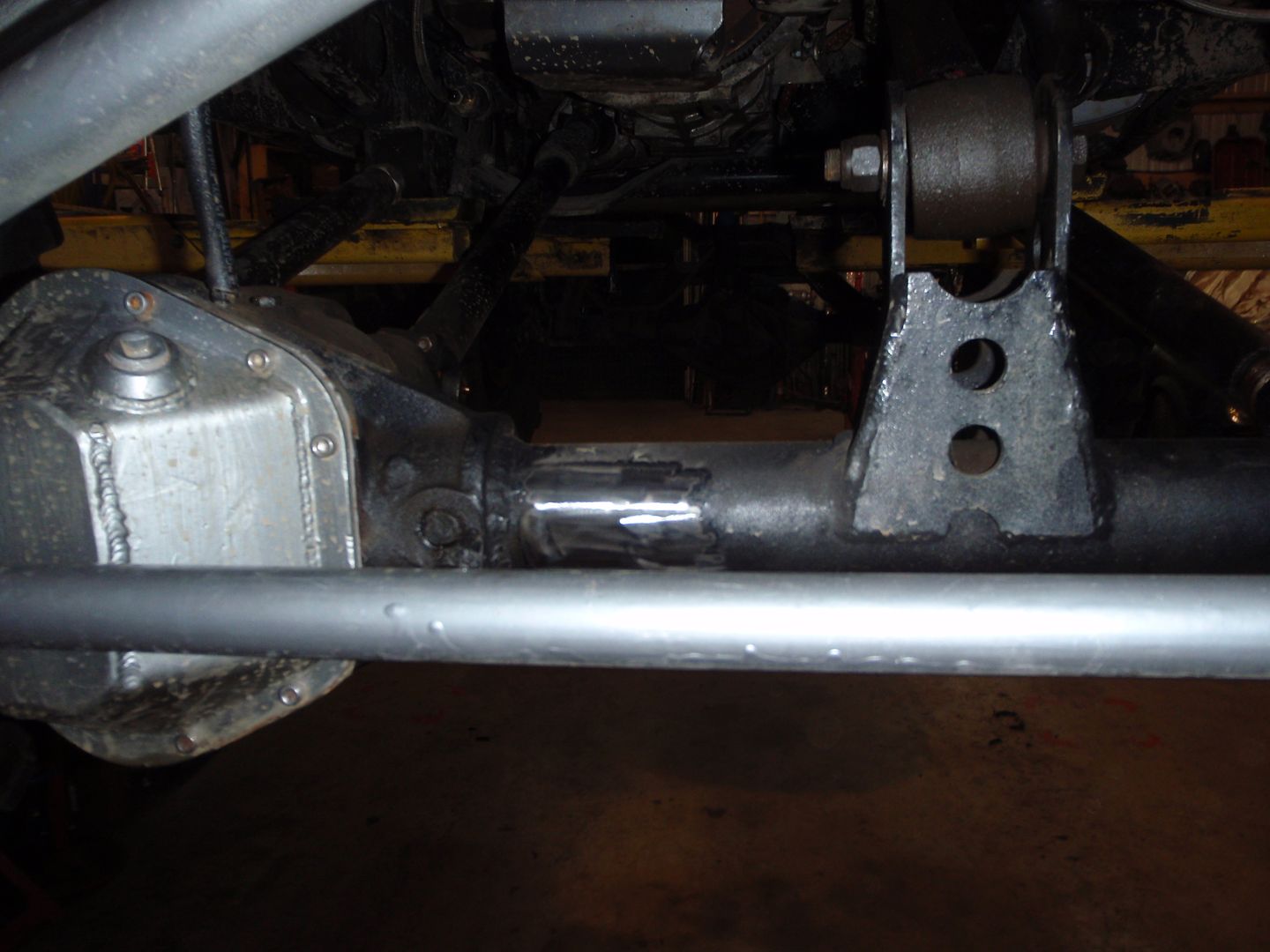

for those who think I can't weld, look away

a teaser while the paint dries

I'm also probably going to relocate my cross-steering arm up onto a high-steer arm then relocated the frame mount of the panhard down so that the bar is parallel with the ground... then it'll handle like a sports car....