I'm starting to wonder about Warn!

The Madd Hunner is at it again.

When I went on a rescue run the other night I was having issues with the winch. It would run a few seconds and stop. Sometimes it would pull 10 feet of cable and quit.

Turns out besides a thermal switch inside the motor cap there is a pressure switch on the air tank. If that is bad the motor will not run thinking the tank is pressurized. Duh! But I did not have it in compressor mode???? Still have not solved that mystery.

I got the guy winched out and just wrapped the cable around the brush guard.

So I called Warn and told them my disappointment with how this junk switch was shutting down my winch. It could have been in BFEgypt and we know how bad things are over there.

The guy I got was apparently a parts guy and repair guy wanta be. He told me some not so believable incorrect facts of which I had already discovered were not true.

The guy I needed was gone to lunch and he really works on them. So while I waited I got next to my tool box and started getting creative.

I had to grind down a 1 1/6 th thin wall deep socket to fit down in the aluminum housing to reach the switch. That was after removing the large aluminum cover and bracket and contactor.

The option was remove the tank which was four long allen head bolts and two fittings that had adapters brazed into the tank. I opted not to mess with those for all the reasons I recall during other projects!

So, while it's all apart let's see what else they have neglected in these newer winches. There is a wimpy thin paper gasket between the steel motor and aluminum housing. Ok so electrolysis has turned that area white with corrosion. No RTV either.

(Just like the other end where the selector lever is)

The end cap on the motor is just stuck on there no gasket or sealant.

Ok, this is great I asked the guy on the phone why that was?

Answer, "well if water gets in there it needs a way to get out"

Is that like cutting holes in your hip boots so if you go over them the water will run out?????

He then said he would just send me a switch. Why thank you thank you very much.

When I recovered from choking I asked him to have the other guy call me.

So I may need my winch in the meantime.

So I made a jumper that all good boys and girls with one of these should go ahead and make up in the comfort of there garage.

We have contact!!

I also made a bit different one for the one in the motor, just in case.

I think I will also give in and order the neoprene cover, you know in case it rains!

The visual aids

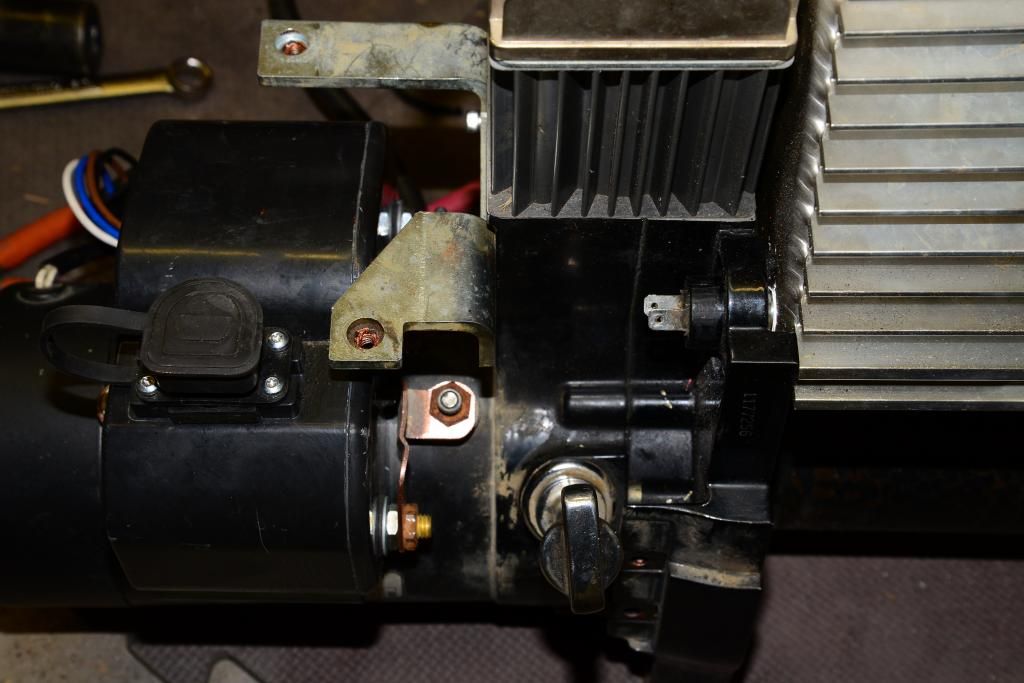

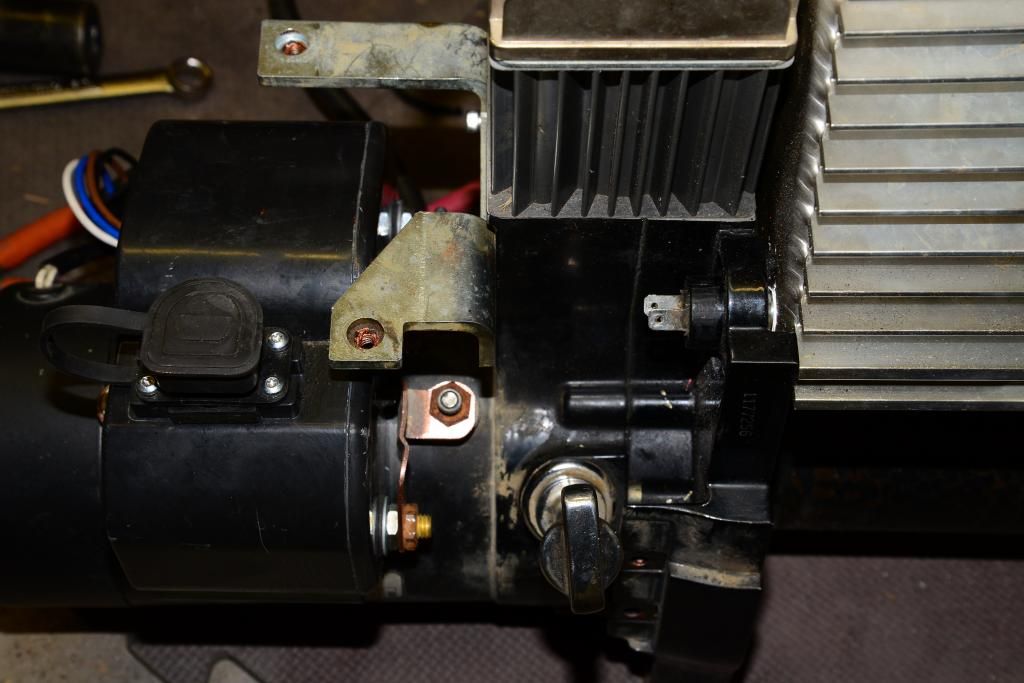

After removing the large aluminum cover you then need to remove this bracket and the contactor box. That big black thing on the left that I suspect is several solenoids but it is glued shut.

This was my test set up.

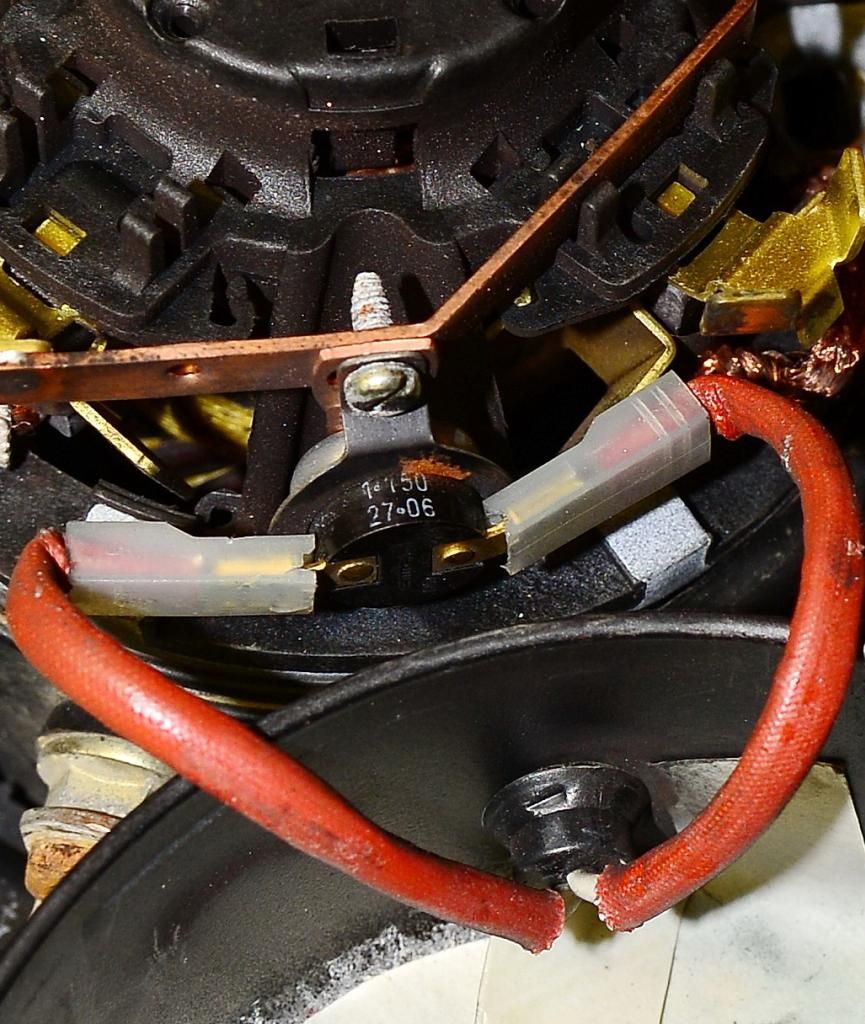

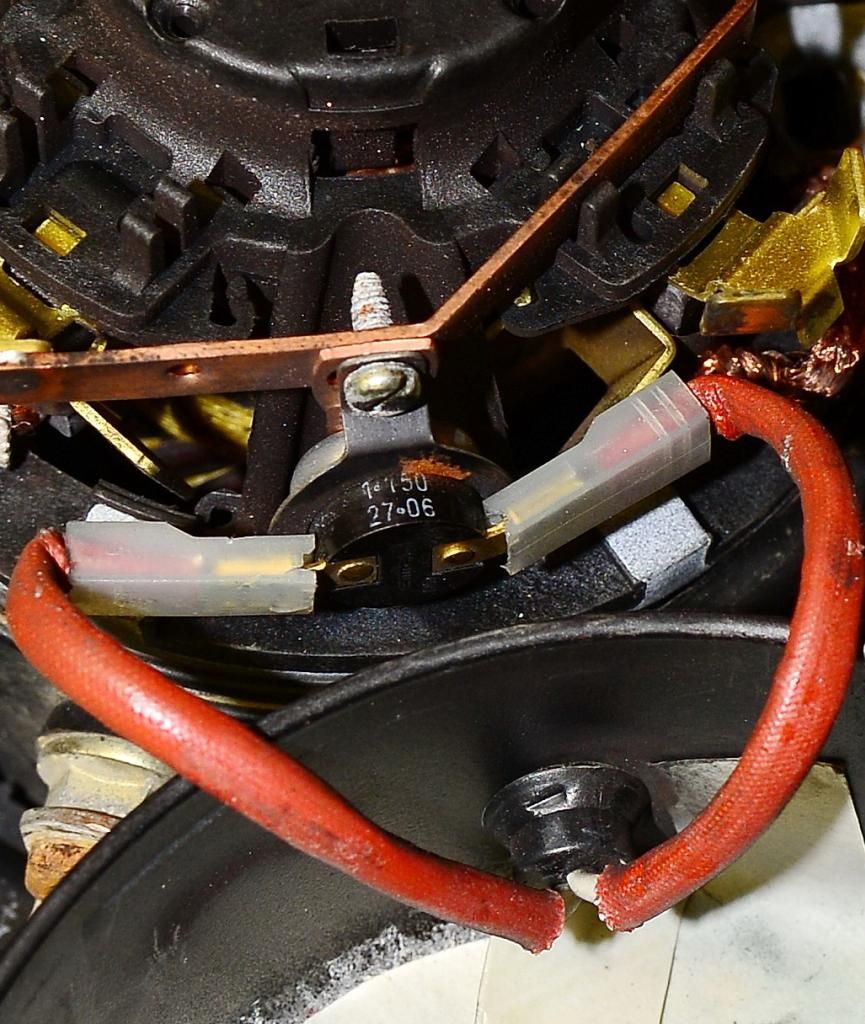

This is the thermal switch in the end cap of the motor.

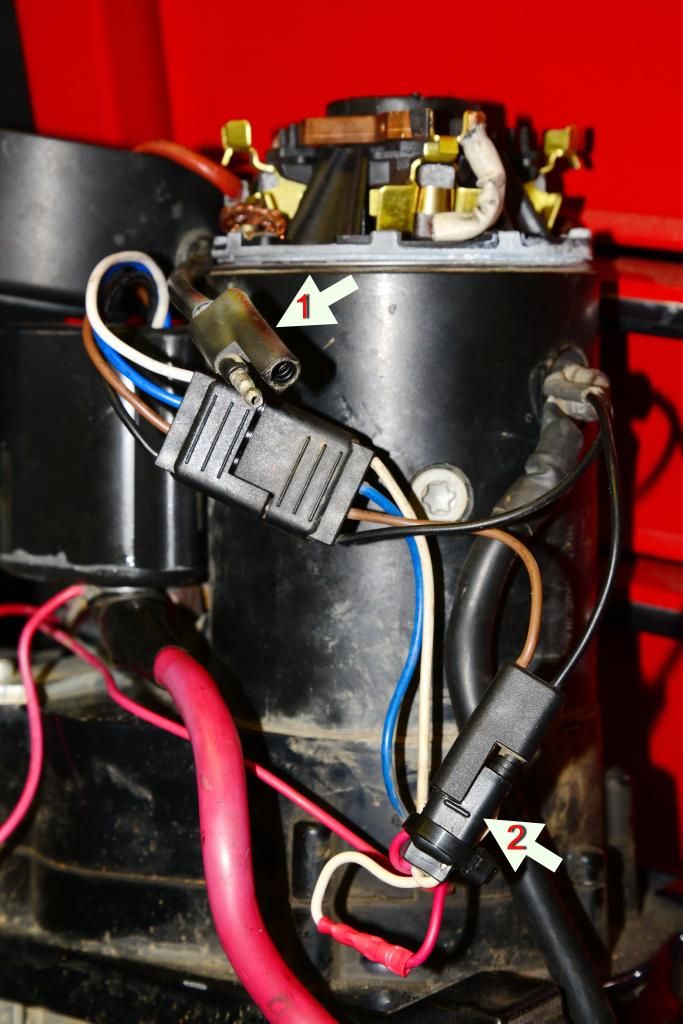

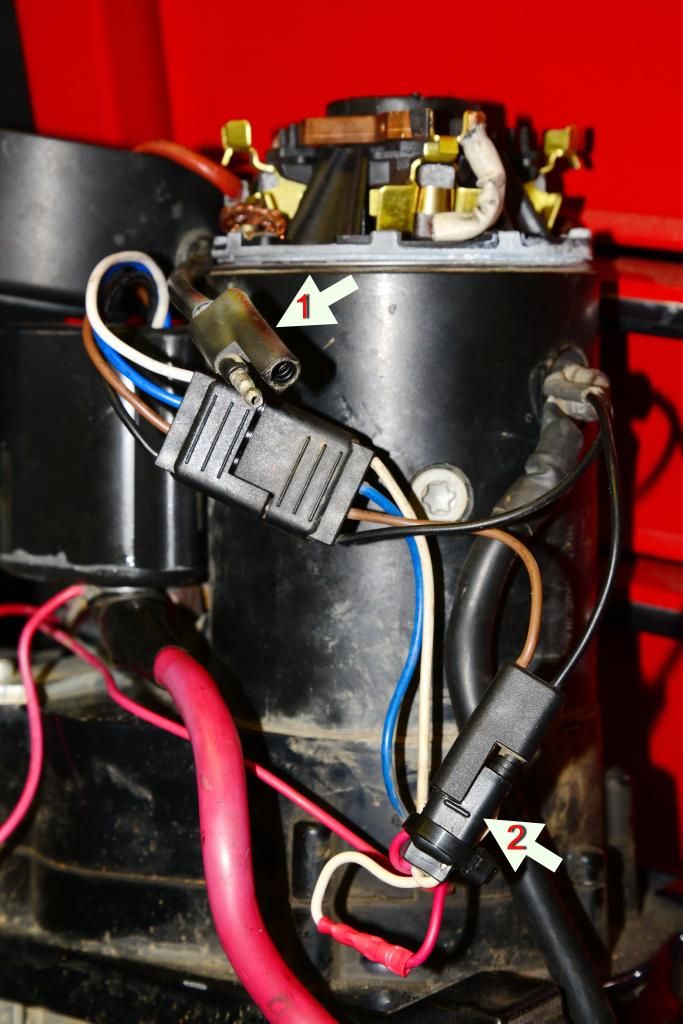

This is the jumper I made in case it melts down. It just bypasses the thermal switch. I used another connector plug and butt spliced the ends together. (arrow 2) At this point I should mention there is a 10 amp flat blade fuse in line. You should get several.

The ground down 1 1/16 socket has to fit thru a hole 1 inch in diameter but the socket that fits the switch is too big.

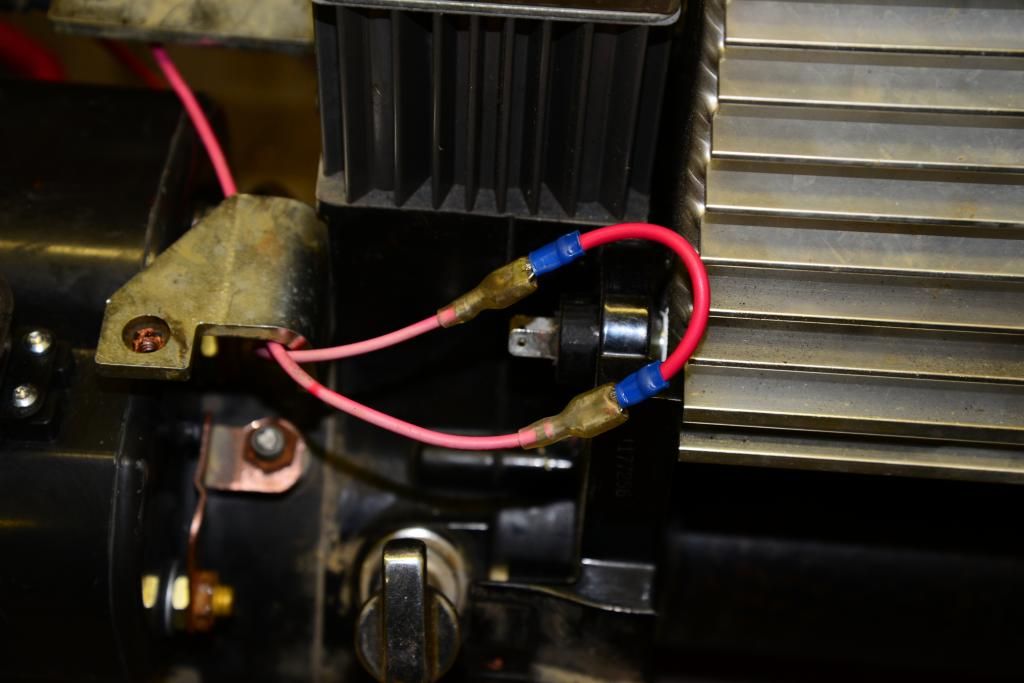

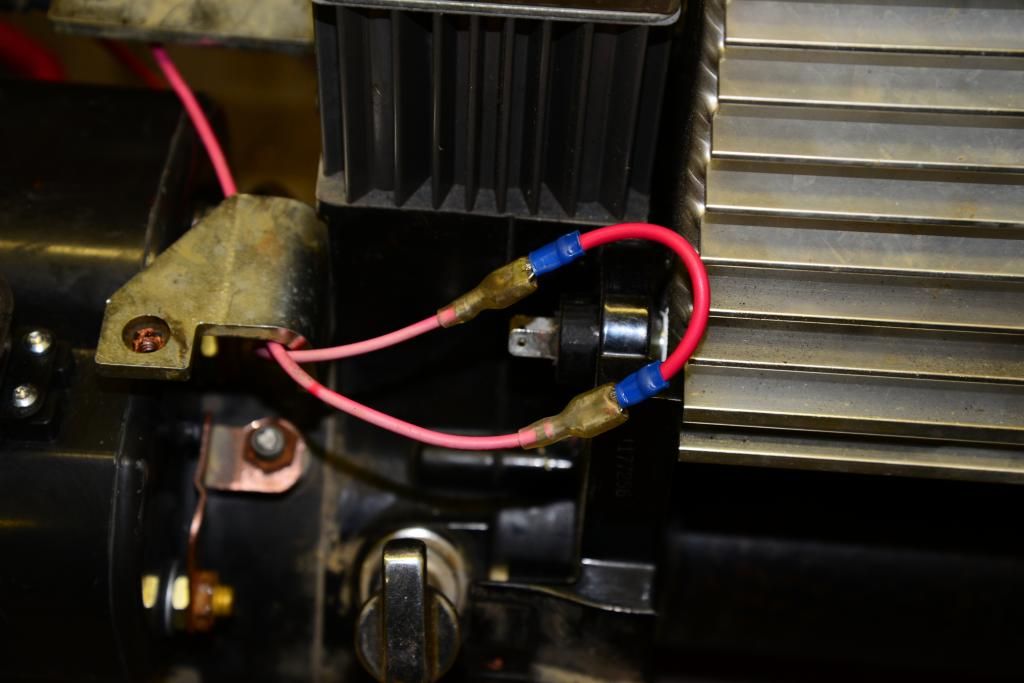

This is the culprit in my case that would not allow the winch to run even though I was not in compressor mode.

Another Hunner Frankenfix. Take note if you work the winch or compressor hard it could overheat and would require human interaction to prevent the smoke from escaping from the motor thus rendering it useless!!!

Whilst I had the thing dissected I also used a wire wheel on the contact plates on the contactor.

The Madd Hunner is at it again.

When I went on a rescue run the other night I was having issues with the winch. It would run a few seconds and stop. Sometimes it would pull 10 feet of cable and quit.

Turns out besides a thermal switch inside the motor cap there is a pressure switch on the air tank. If that is bad the motor will not run thinking the tank is pressurized. Duh! But I did not have it in compressor mode???? Still have not solved that mystery.

I got the guy winched out and just wrapped the cable around the brush guard.

So I called Warn and told them my disappointment with how this junk switch was shutting down my winch. It could have been in BFEgypt and we know how bad things are over there.

The guy I got was apparently a parts guy and repair guy wanta be. He told me some not so believable incorrect facts of which I had already discovered were not true.

The guy I needed was gone to lunch and he really works on them. So while I waited I got next to my tool box and started getting creative.

I had to grind down a 1 1/6 th thin wall deep socket to fit down in the aluminum housing to reach the switch. That was after removing the large aluminum cover and bracket and contactor.

The option was remove the tank which was four long allen head bolts and two fittings that had adapters brazed into the tank. I opted not to mess with those for all the reasons I recall during other projects!

So, while it's all apart let's see what else they have neglected in these newer winches. There is a wimpy thin paper gasket between the steel motor and aluminum housing. Ok so electrolysis has turned that area white with corrosion. No RTV either.

(Just like the other end where the selector lever is)

The end cap on the motor is just stuck on there no gasket or sealant.

Ok, this is great I asked the guy on the phone why that was?

Answer, "well if water gets in there it needs a way to get out"

Is that like cutting holes in your hip boots so if you go over them the water will run out?????

He then said he would just send me a switch. Why thank you thank you very much.

When I recovered from choking I asked him to have the other guy call me.

So I may need my winch in the meantime.

So I made a jumper that all good boys and girls with one of these should go ahead and make up in the comfort of there garage.

We have contact!!

I also made a bit different one for the one in the motor, just in case.

I think I will also give in and order the neoprene cover, you know in case it rains!

The visual aids

After removing the large aluminum cover you then need to remove this bracket and the contactor box. That big black thing on the left that I suspect is several solenoids but it is glued shut.

This was my test set up.

This is the thermal switch in the end cap of the motor.

This is the jumper I made in case it melts down. It just bypasses the thermal switch. I used another connector plug and butt spliced the ends together. (arrow 2) At this point I should mention there is a 10 amp flat blade fuse in line. You should get several.

The ground down 1 1/16 socket has to fit thru a hole 1 inch in diameter but the socket that fits the switch is too big.

This is the culprit in my case that would not allow the winch to run even though I was not in compressor mode.

Another Hunner Frankenfix. Take note if you work the winch or compressor hard it could overheat and would require human interaction to prevent the smoke from escaping from the motor thus rendering it useless!!!

Whilst I had the thing dissected I also used a wire wheel on the contact plates on the contactor.